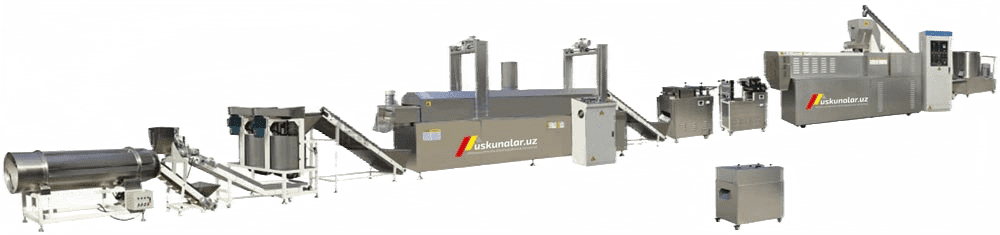

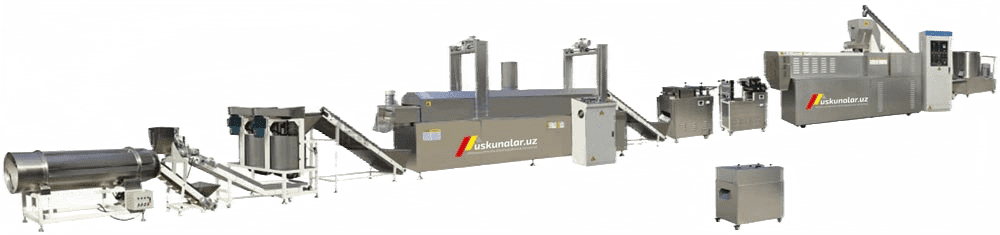

This chip making line consists of flour mixer, screw conveyor, twin screw extruder, stretching and cutting equipment, belt conveyor, frying system, vibration equipment, chip forming machine, oil filter, seasoning adding equipment, and cooling conveyor consists of.

| FLOUR MIXER |

|

Power: 3.7 KW |

| Capacity: 50 - 60 kg / 1 time |

| Dimensions: 950 x 750 x 1200 mm |

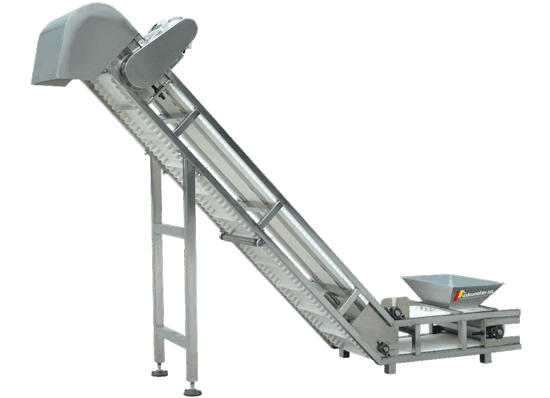

| SCREW CONVEYOR |

| Power: 1.1 kW |

|

| Dimensions: 2000 x 600 x 2500 mm |

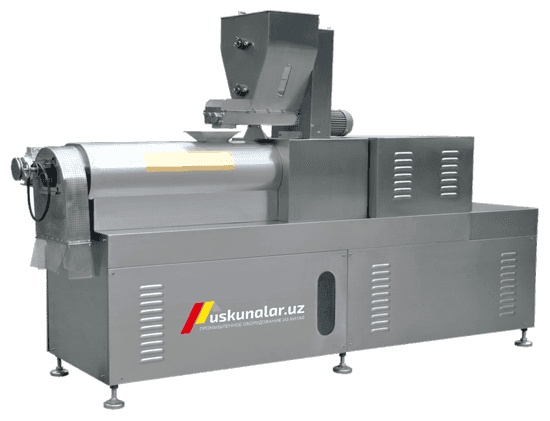

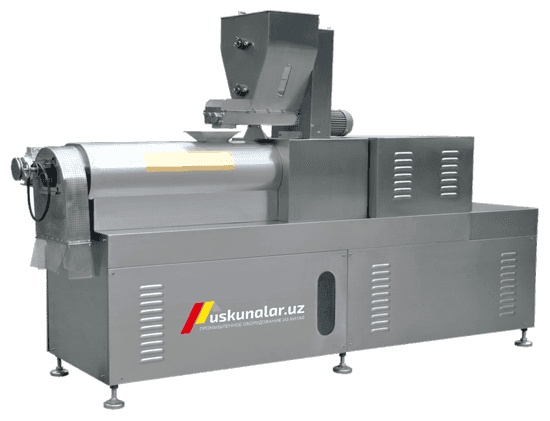

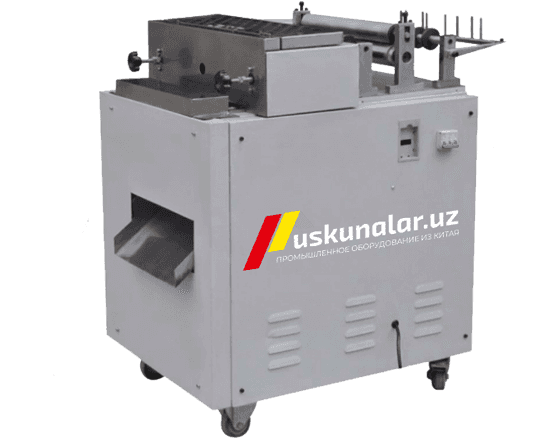

| TWIN SCREW EXTRUDER |

|

Installed power: 35 Kw |

| Engine power: 22 Kwt |

| Power supply: 0.4 Kwt |

| Cutting: 0.75 KW |

| Heating: 10 KW |

| Oil pump: 0.37 KW |

| Output volume: 120 - 150 kg / hour |

| Dimensions: 3.1 x 0.8 x 1.9 meters |

| Screw material: 38Crmoal |

| Engine Center: Siemens |

| Relay: ABB |

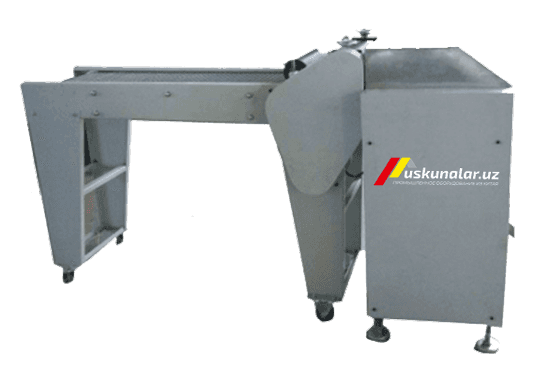

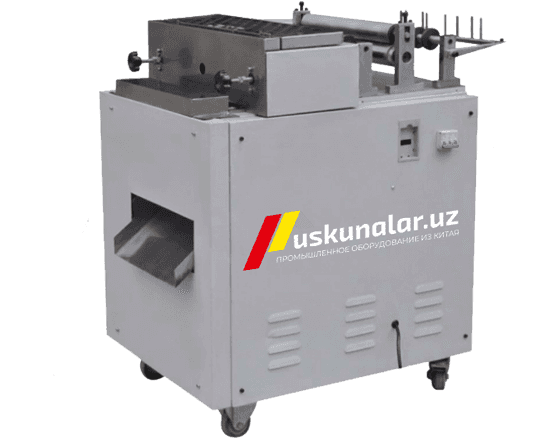

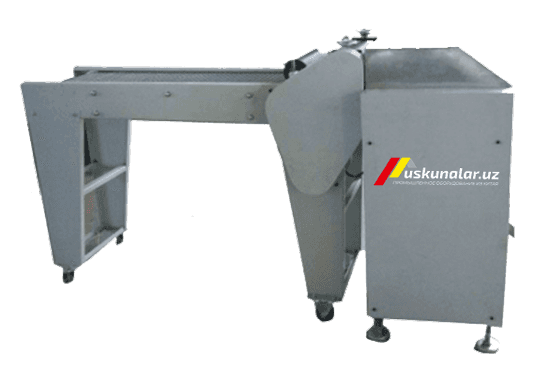

STRETCHING AND CUTTING EQUIPMENT

(to make long chips) |

| Power: 1.1 KW |

|

| Dimensions: 1.95 x 0.8 x 1.1 meters |

| Weight: 300 kg |

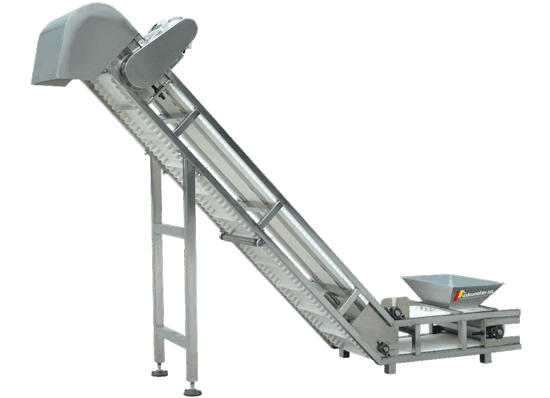

| BELT CONVEYOR |

|

Power: 1.1 KW |

| Dimensions: 2.6 x 0.65 x 1.7 meters |

| Weight: 220 kg |

| Material: stainless steel |

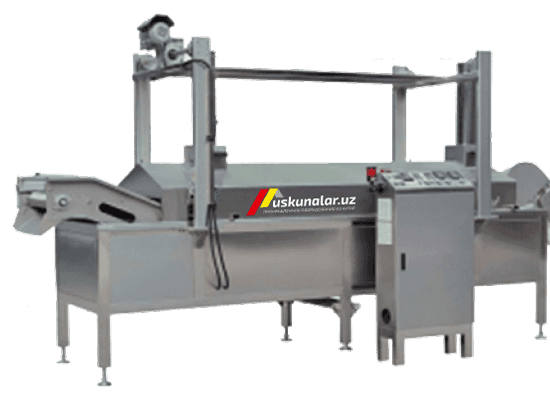

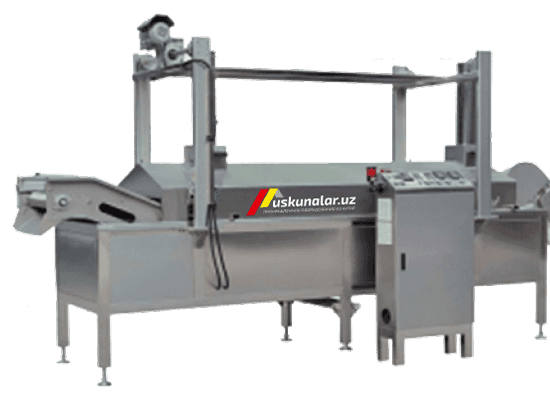

CONTINUOUS AUTOMATIC FRYING SYSTEM WITH OIL TANK

(centralized management) |

| Size of frying equipment: 3710 x 1260 x 2120 mm |

|

| Internal dimensions: 2600 x 600 x 350 mm |

| Power: 51 KW |

| Temperature control range: 0 – 260 Co |

| Oil tank dimensions: 1200 x 1500 x 1900 mm |

| Power: 15 Kwt |

| Charging pump: 2.2 KW |

| VIBRATING EQUIPMENT |

|

1.Vibration equipment removes oil from the surface of the product. |

| 2. The vibrating part of the vibrating equipment consists of a stainless steel mesh, which can be removed and cleaned easily. |

| 3. Excess oil and debris can be removed from the slag on the side. |

| 4. The motor vibration frequency can be adjusted. |

| 5. Dimensions: 2200 x 1150 x 970 mm |

| 6. Equipment body: 0.36 KW |

| HEXAGON CHIPS FORMING EQUIPMENT |

| Power: 1.5 KW |

|

| Dimensions: 1.5 x 0.65 x 1.2 meters |

| Equipment body: stainless steel |

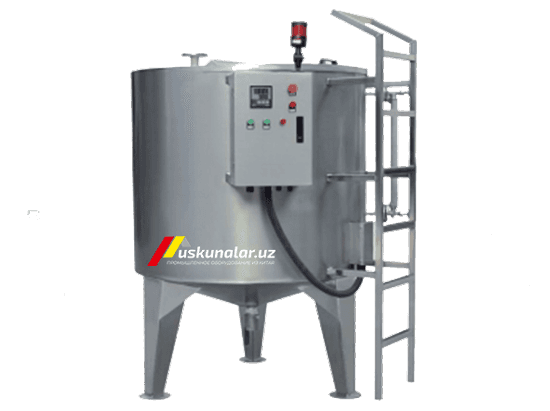

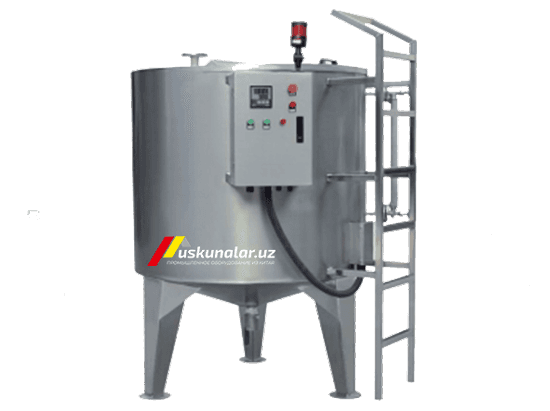

| OIL FILTER |

|

1. The oil filter is connected to the frying equipment. |

| 2. It consists of two circulating pumps, one connected to the frying equipment to filter the fried oil, and the other to the continuous filter of the fried oil storage filter. |

| 3. The equipment is equipped with a 300 mesh stainless steel strainer to completely filter out residual frying oil. |

| 4. The filter can be removed and reused. There are no consumables in this build. |

| 5. Dimensions: 1050 x 910 x 1100 meters |

| 6. Power: 5.5 KW |

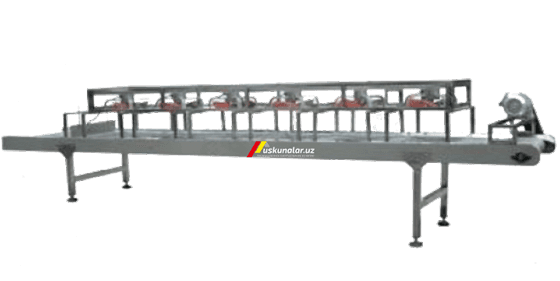

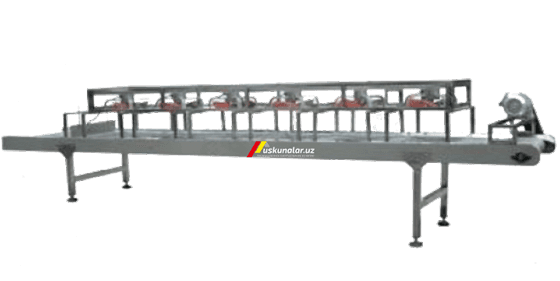

| FLAVORING SPICES ADDITION LINE |

| Dimensions: 6 x 1 x 2.2 meters |

|

| Power: 4.25 KW |

COOLING CONVEYOR

(with three fans) |

|

Dimensions: 5 x 0.7 x 1.3 meters |

| Power: 1.1 KW |