This set of equipment is used to produce stretch film (stretch) LDPE or LLDPE (Linear Low Density Polyethylene).

1. The propeller stem and cylinder are made of 38CRMOALA alloy and treated with nitrogen. It has the advantage of corrosion resistance and durability.

2. The water cooling system should provide the best transparency effect, which will increase the productivity of the extruder.

3. The receiving equipment is equipped with a friction rewinder, and the equipment is equipped with an edge correction device to ensure quality.

|

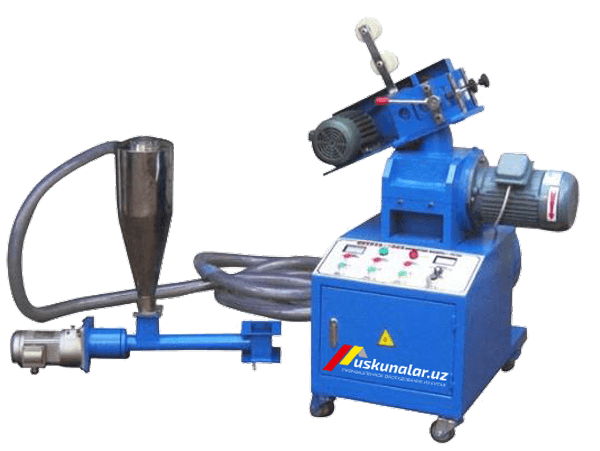

EKSTRUDER

|

| 1. |

Material |

LDPE, LLDPE (linear low density polyethylene) |

| 2. |

Maximum film width |

1000 mm ( 500 mm x 2 pcs ) |

| 3. |

Film thickness |

0.01 mm - 0.05 mm |

| 4. |

Extruder screw diameter |

65 mm |

| 5. |

L/D ratio |

28:1 |

| 6. |

Screw material |

38CrMoAI nitriding treatment |

| 7. |

Screw speed |

20 - 120 rpm |

| 8. |

Extruder motor |

22 KW (inverter control) |

| 9. |

Barrel heating power |

18 KW ( 3 zones ) |

| 10. |

Screen change |

manually |

| 11. |

Permissible die length |

1150 mm |

| 12. |

Die material |

45Cr |

| 13. |

Die heating power |

16 KW ( 4 zones ) |

| 14. |

Die joint heating power |

3 KW ( 1 zone ) |

| 15. |

Retarder style |

ZLYJ200 |

| 16. |

Ability |

40 - 60 kg / hour |

| 17. |

Weight |

3000 kg |

| 18. |

Dimentions |

6500 x 2800 x 1900 mm |

|

WINDING DEVICE

|

| 1. |

Permissible length of rollers |

1150 mm |

| 2. |

Diameter of the main chilled roller |

320 mm |

| 3. |

Main roller cooling style |

Internal cooling with recirculation |

| 4. |

R3/4'' main cooling roller swivel joint type |

R3 / 4 ’’ ( in one direction ) |

| 5. |

Diameter of the pull-out cutting roller |

100 mm ( 2 pcs ) |

| 6. |

Cutting roller diameter |

90 mm ( aluminum ) |

| 7. |

Winding roller diameter |

320 mm |

| 8. |

Maximum winding diameter |

600 mm |

| 9. |

Winding style |

Passive winding |

| 10. |

Winding change style |

Dual working stations and automatic bobbin changing and cutting |

| 11. |

Power of winding and drawing motor |

2.2 KW (invertor control) |

| 12. |

Forklift |

1 piece |

| 13. |

PLC |

1 piece |

| 14. |

Touch screen |

1 piece |

| 15. |

Automatic edge recycling machine |

1 piece |

|

CONTROL CABINET

|

| 1. |

Automatic barrel and die temperature control (9 zones) |

| 2. |

Independent control switches including amp, rpm and m / min meters for the whole machine |

|

SPARE PARTS

|

| 1. |

Temperature controller |

1 piece |

| 2. |

Current meter |

1 piece |

| 3. |

Voltage meter |

1 piece |

| 4. |

Thermocouple |

2 pcs |

| 5. |

Pushbutton switch |

2 pcs |

| 6. |

Heater |

2 pcs |

| 7. |

Filter |

1 meter |

| 8. |

Tool kit |

1 piece |