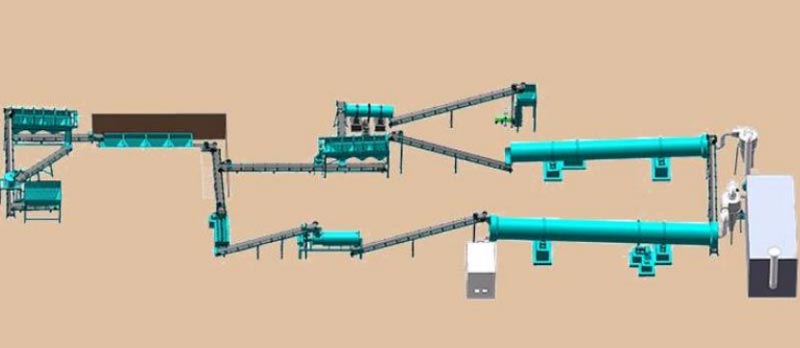

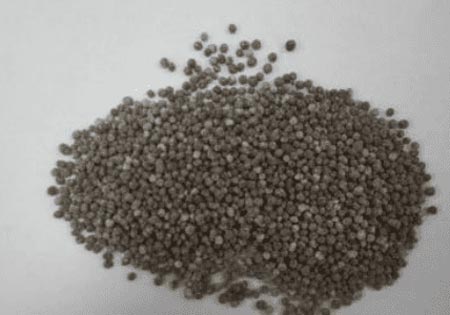

Image 1.

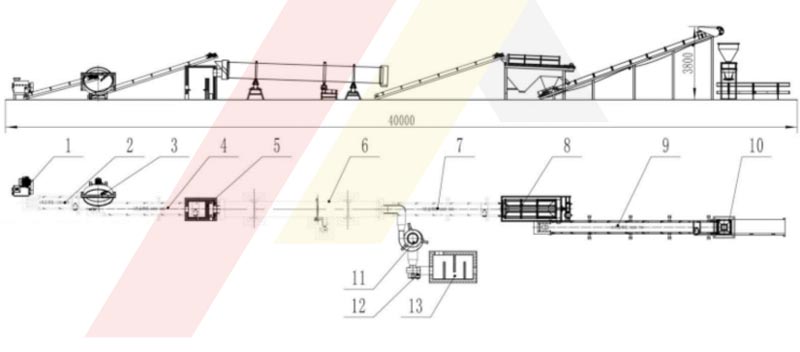

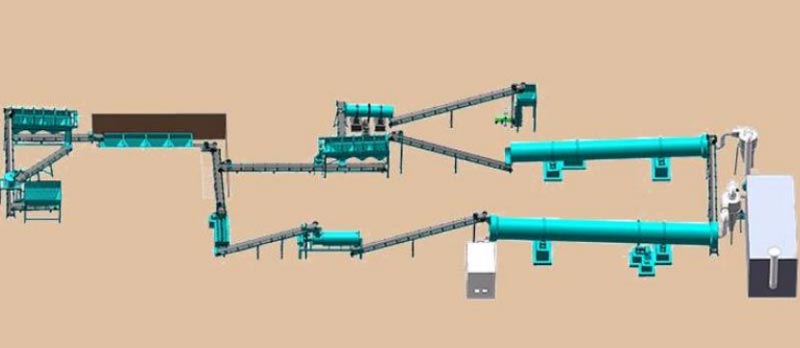

Image 2.

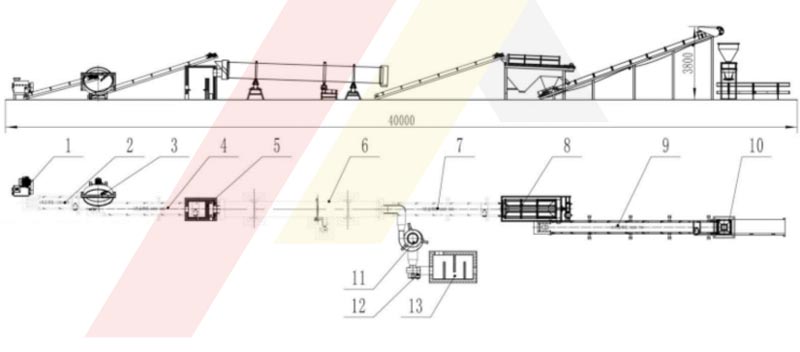

1. Semi-wet material crusher.

2. Belt conveyor 4 m long.

3. Disc granulator.

4. Belt conveyor with a length of 7 m.

5. Hot plate.

6. Dryer.

7. Belt conveyor 7 m long.

8. Sifter with oscillating cylinder.

9. Belt conveyor 10 m long.

10. Packing machine.

11. Cyclone dust collector.

12. Air fan.

13. Dust chamber.

| Movable type compost turner |

|

| Model |

US-XXF-2000 |

| Power |

30 h.p. |

| Turning width |

2 m |

| Turning depth |

0.6-0.8 m |

| Dimensions |

3.3x2.4x2 m |

| Distance between rows |

0.5-0.8 m |

| Maximum speed |

2200 pieces/min |

| Working speed |

7.58 m/min |

| Maximum productivity |

380 m3/hour |

| Function |

used for fermentation material |

| GRANULATION PROCESS |

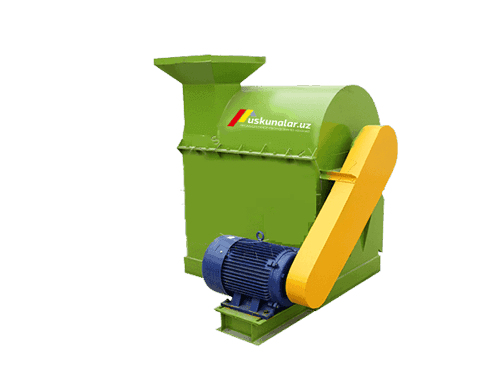

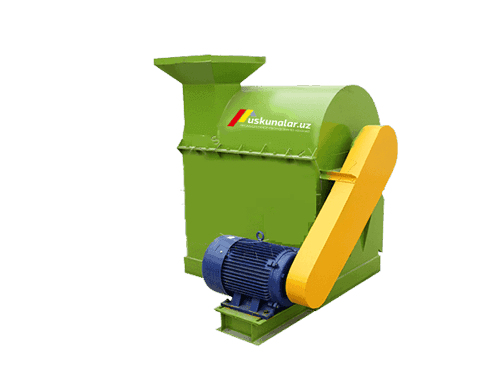

| Semi Wet Material Crusher |

|

| Model |

US-XSF-40 |

| Entry size |

400x240 mm |

| Grit crushing |

50 m |

| Dimensions |

1.2x1.35x0.9 m |

| Function |

Crushing large material |

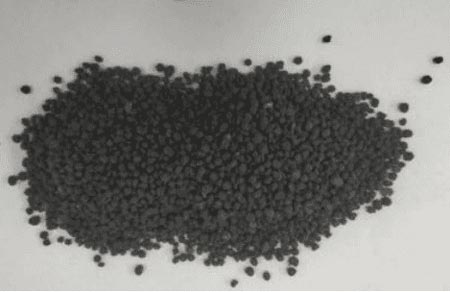

| Disc granulator |

|

| Model |

US-XYZ-1500 |

| Performance |

0,5-0,8 tons/hour |

| Disc diameter |

1500 mm |

| Moisture while feeding |

around 30% |

| Feed material size |

50 mesh |

| Dimensions |

1,76x1,5x1,95 m |

| Function |

wet granulation |

| Hot stove |

|

| The size is too large, need to be built on site by the customer, we will provide the drawing |

| Function |

providing a heat source for the dryer |

| CONNECTING PIPES |

| Rotary dryer |

|

| Model |

US-XHG-0808 |

| Speed |

6 pieces/min |

| Speed |

0,8 m |

| Length |

8 m |

| Case thickness |

8 mm |

| Mounting angle |

3-5 ° |

| Inlet temperature |

≥300 ℃ |

| Material |

boiler steel Q235B |

| Function |

fertilizer drying |

| Sifter with oscillating cylinder |

|

| Model |

US-XGS-1030 |

| Speed |

21 pieces/min |

| Dimensions |

1x3 m |

| Function |

used for screening various hard materials |

| Grid size can be customized |

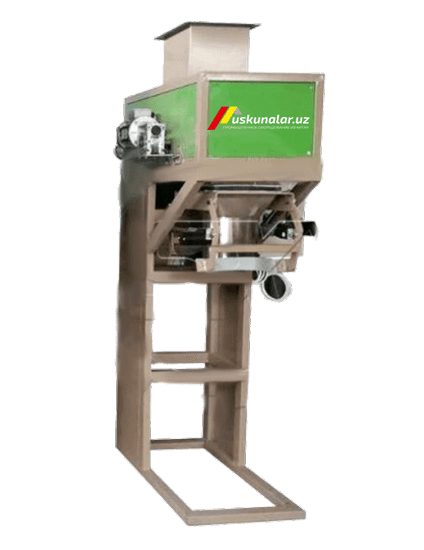

| Packaging scales |

|

| Model |

US-XKB-01 |

| Weight range |

20-50 kg/bag |

| Packing speed |

4 bag/min |

| Permissible error |

± 0,2% |

| Including belt conveyor, bag sewing machine, electric control box and air compressor |

| CONNECTING PIPES |

| Cyclone dust collector |

|

| Model |

US-XSKL-900 |

| Size |

φ900 |

| Function |

collection of dust caused by the fan in cooling process |

| Air fan |

|

| Model |

US-5C |

| Air volume |

5360-9871 m3/s |

| Air pressure |

1549-2265 Pa |

| Speed |

2900 pieces/min |

| Function |

Exhaust gases to the outside |

| Dust chamber |

|

| The size is too large, need to be built on site by the customer, we will provide the drawing |

| Function |

exhaust gases to the outside |

| Connecting pipes |

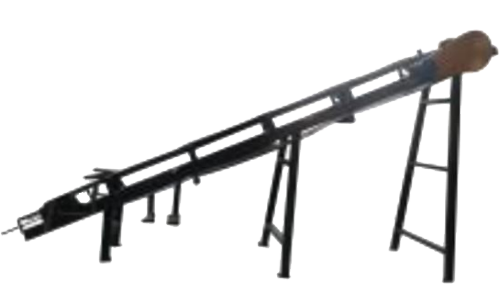

| Belt conveyor |

|

| Power |

13 KW |

| Width |

500 mm |

| Length |

28 meter (4 sets) |

| Function |

Material transport, connection of the entire production line |

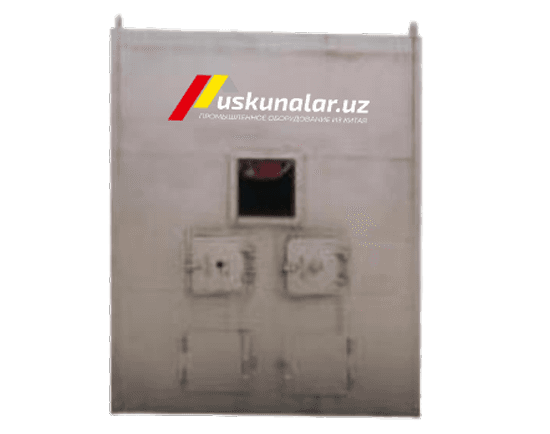

| Control Panel |

|

| Model |

US-C-01 |

| Electrical components |

CHNT |

| Function |

on/off control of the entire line |