ABOUT THE LINE

Automatic biscuit machine production line, with original design, compact structure and high automatic. All working procedures that from dough mixing, molding, waste recycling, baking to cooling can be completed automatically in one line. Hundreds of molds and dozens of technology recipes make it possible to produce all kinds of popular biscuits, such as soft, hard and cream biscuit.

|

MACHINE LIST

|

| № |

Machine name |

Quantity |

| 1 |

Flour mixer |

2 set |

| 2 |

Soft biscuit forming machine |

1 set |

| 3 |

Hard biscuit forming machine |

1 set |

| 4 |

Entering turning around |

1 set |

| 5 |

Outing turning around |

1 set |

| 6 |

Electric tunnel oven |

20 meter |

| 7 |

Oil spray machine |

1 set |

| 8 |

Cooling conveyor |

10 meter |

| 9 |

Packing table |

6 meter |

| 10 |

Control box |

1 set |

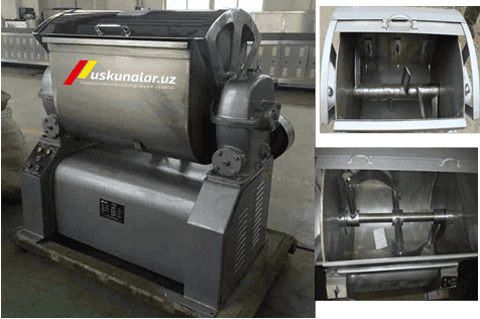

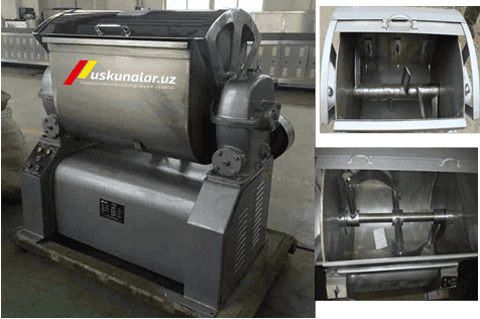

| 1. FLOUR MIXER |

|

Model |

US-75 |

| Voltage |

380 V/50 Hz |

| Capacity |

75 kg/hour |

| Power |

4 KW |

| Mixing time |

5-15 min |

| Weight |

550 kg |

| Dimensions |

1180x710x1220 mm |

| Material |

hopper: stainless steel 304

machine shell: carbon steel |

| Function |

It is stirring machine which crumples up flour powder and water into dough or other materials and is independently used with other machines. |

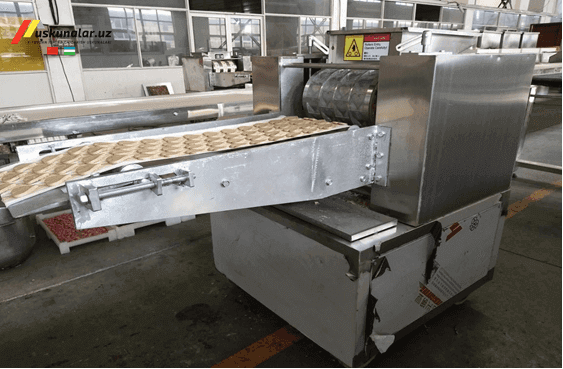

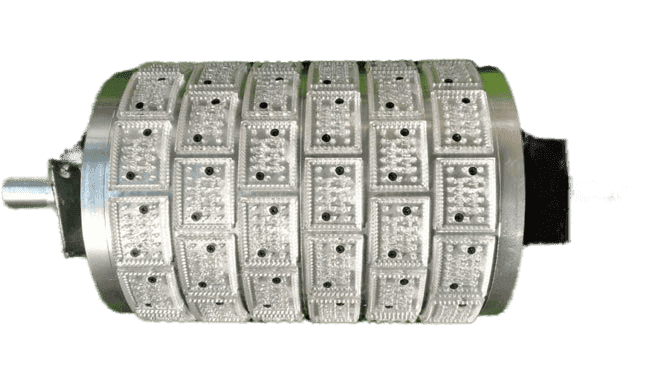

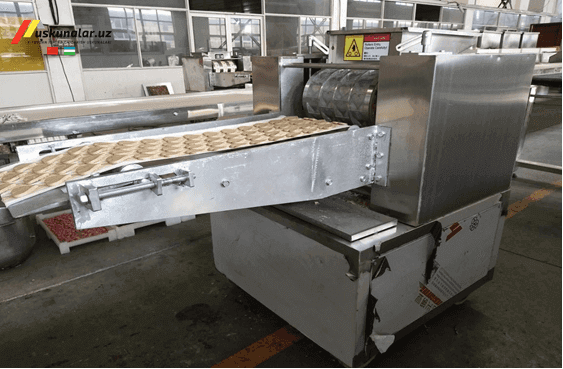

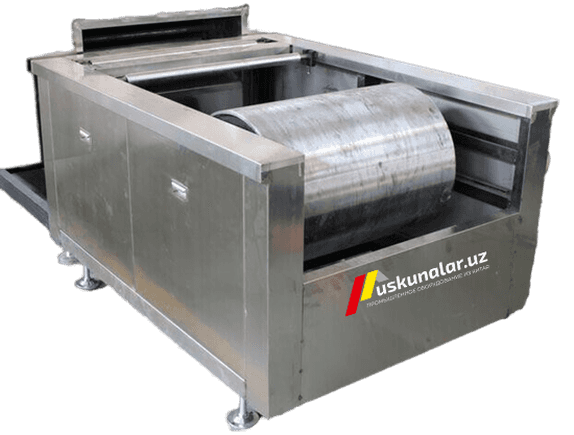

| 2. SOFT BISCUIT FORMING MACHINE |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Capacity |

150-200 kg/hour |

| Power |

2.2 KW |

| Roller diameter |

248 mm |

| Weight |

600 kg |

| Dimensions |

1800x1000x1300 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| Function |

After putting stirring flour powder into the machine hopper, they are one time shaped into unripe biscuit. |

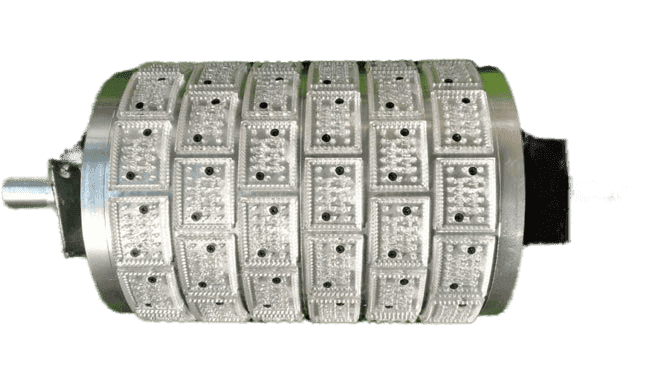

| 3. HARD BISCUIT FORMING MACHINE |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Capacity |

150-150 kg/hour |

| Power |

4 KW |

| Weight |

2500 kg |

| Dimensions |

4800x1050x1550 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| Function |

After putting stirring flour powder into the machine hopper, all kinds of middle and high grade biscuit and thin biscuit through three stages roller and roller cutting molds. |

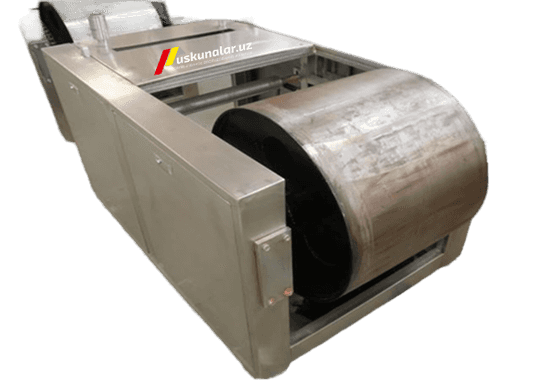

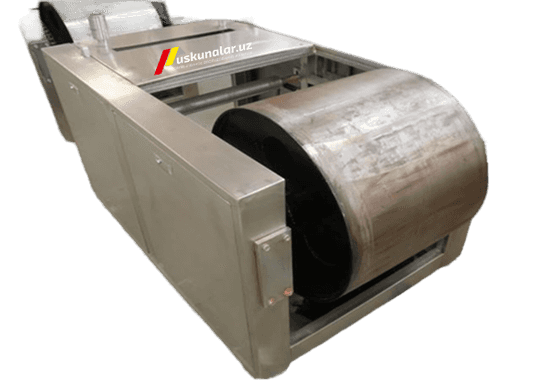

| 4. ENTERING TURNING AROUND |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Power |

passive |

| Weight |

380 kg |

| Dimensions |

1300x1000x900 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| Function |

It is the main parts of the production line, connect the forming machine and the tunnel oven, continuously convey the biscuit to the tunnel oven for baking by the net belt. |

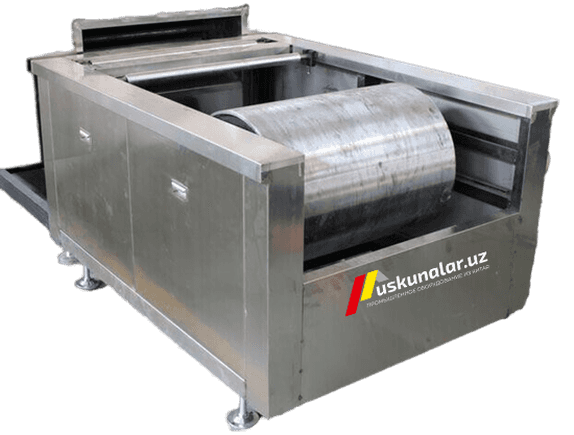

| 5. OUTING TURNING AROUND |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Power |

3 KW |

| Weight |

450 kg |

| Dimensions |

1500x1000x900 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| Function |

It can drive and tightening the net belt in the tunnel, also use for convey the baked biscuit out of the oven for cooling. |

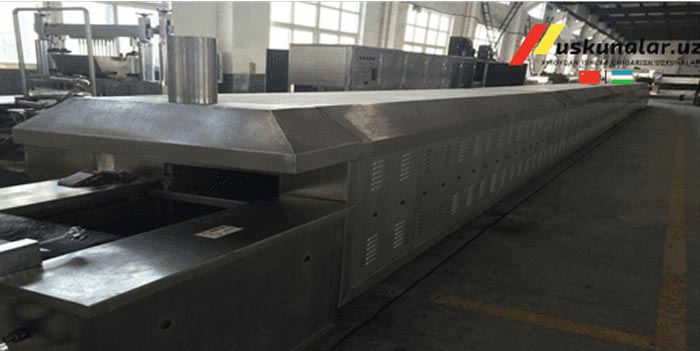

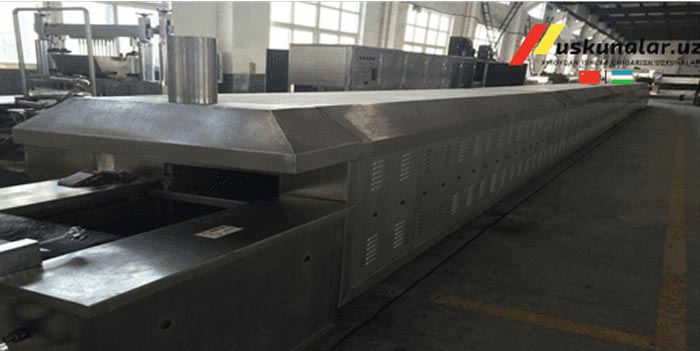

| 6. ELECTRIC TUNNEL OVEN |

|

Model |

US-400 |

| Capacity |

100-200 kg/hour |

| Voltage |

380 V/50 Hz |

| Length of oven |

20 meter |

| Heating method |

Electric |

| Power |

102.6 KW |

| Weight |

4 tons |

| Dimensions |

20000x1050x1300 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| 7. OIL SPRAY MACHINE |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Power |

3 KW |

| Weight |

500 kg |

| Dimensions |

1500x1000x1350 mm |

| Material |

machine shell: stainless steel 304

frame: carbon steel |

| Function |

The baked hot biscuit will be conveyed to the oil-spraying machine right after the tunnel oven, which is necessary to produce high-quality, better color biscuit. |

| 8. COOLING CONVEYOR |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Way of conveying |

net belt |

| Power |

3 KW |

| Weight |

500 kg |

| Dimensions |

10000x800x750 mm |

| Material |

machine shell: stainless steel 304 |

| Function |

This equipment is fully cooled before the biscuits are delivered to the packaging machine to ensure the quality of the biscuits after packaging and to extend the shelf life. |

| 9. PACKING TABLE |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Way of conveying |

PU belt |

| Power |

0.75 KW |

| Weight |

350 kg |

| Dimensions |

6000x700x770 mm |

| Material |

machine shell: stainless steel 304 |

| Function |

The packaging table can help put the biscuits arranged in a row into the packaging machine track in front of the packaging machine to speed up the packaging. |

| 10. CONTROL BOX |

|

Model |

US-400 |

| Voltage |

380 V/50 Hz |

| Weight |

150 kg |

| Dimensions |

800x400x1300 mm |

| Material |

machine shell: stainless steel 304 |

| Function |

Intelligent temperature control instrument. |

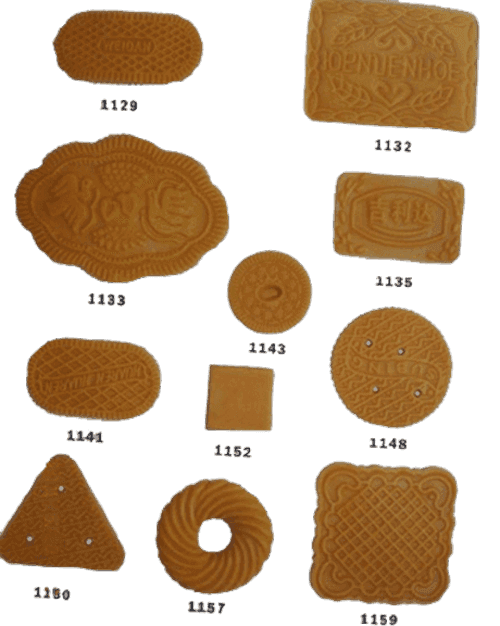

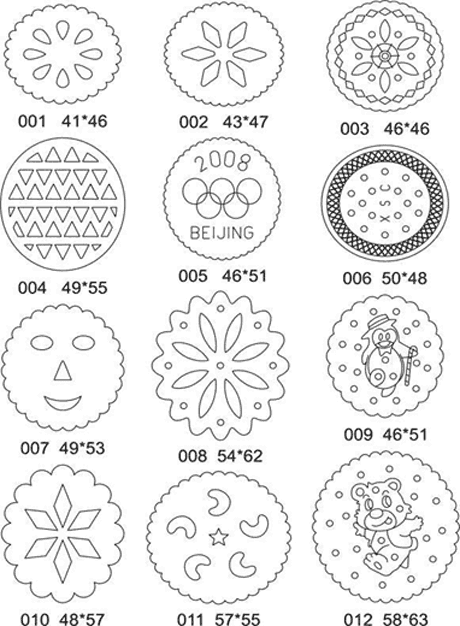

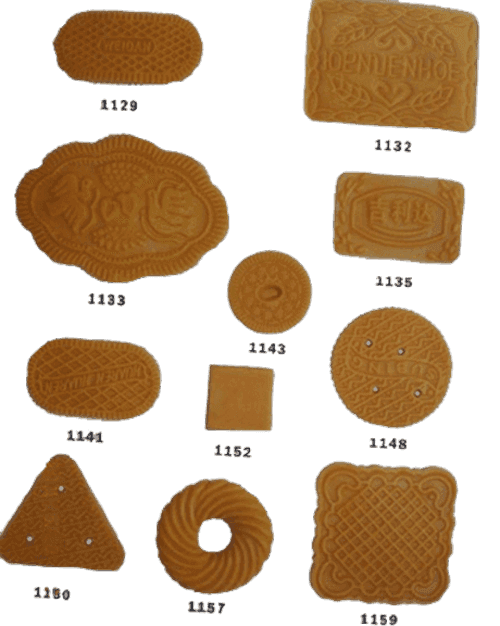

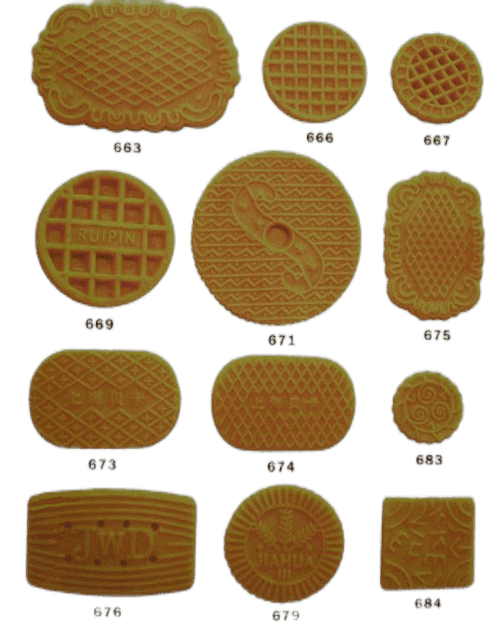

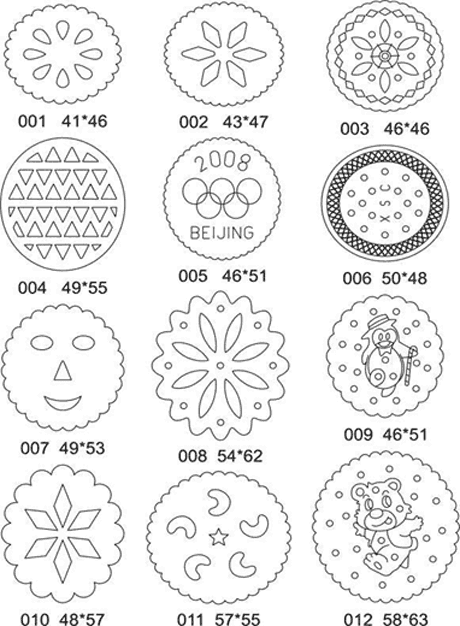

MOLDS

(can customized according to customer need) |

|

|

|

|

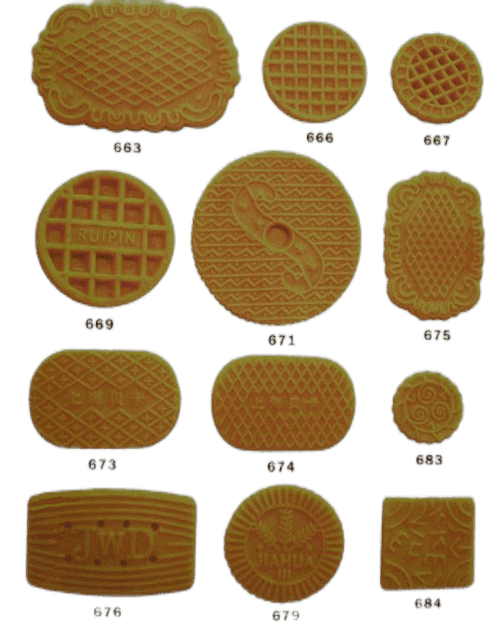

| OTHER MOLD DESIGN FOR REFERENCE |

|

|

|

|