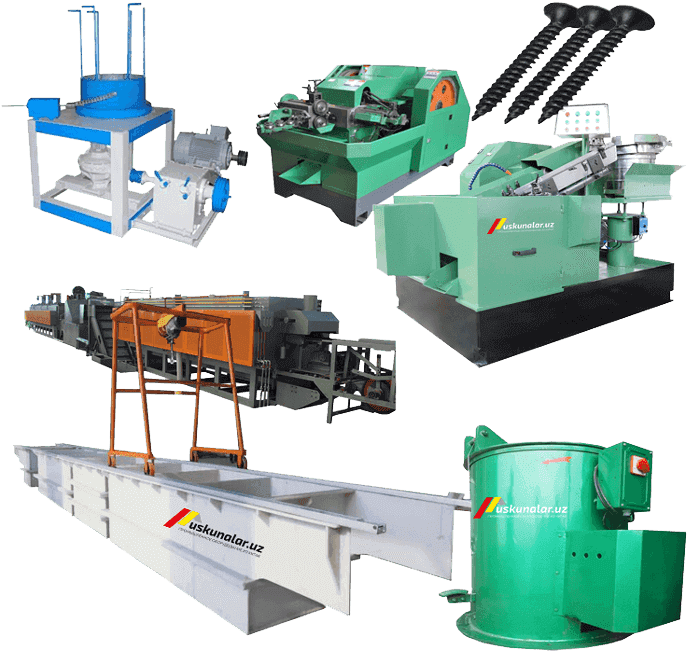

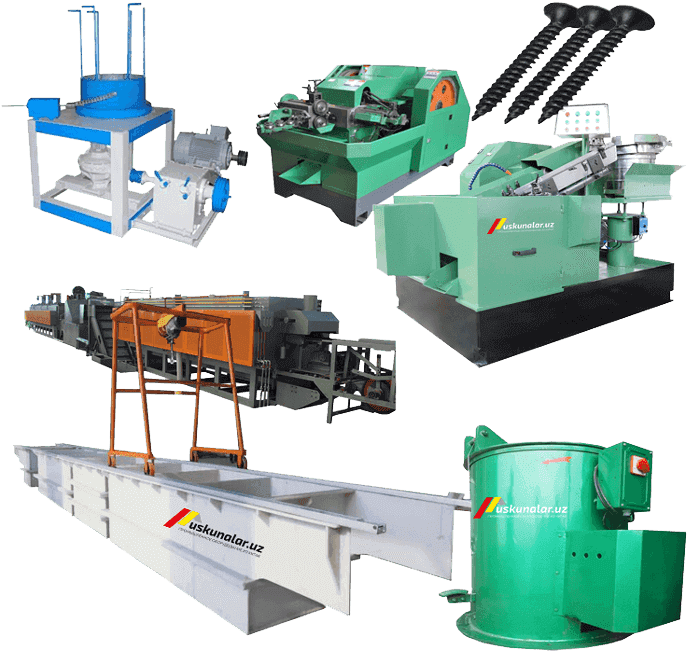

Among the construction materials, one of the most widely used products is a drywall screw. It is always liked by customers due to its wide range of applications and long service life. This self-tapping screw, the drywall screw production line is a complex process that requires a variety of machines and processes to produce a high-quality product. The raw material used in this screw production line is 2.9 mm black wire, which is then drawn through a wire drawing machine. This equipment is used to reduce the diameter of the wire and create a uniform shape.

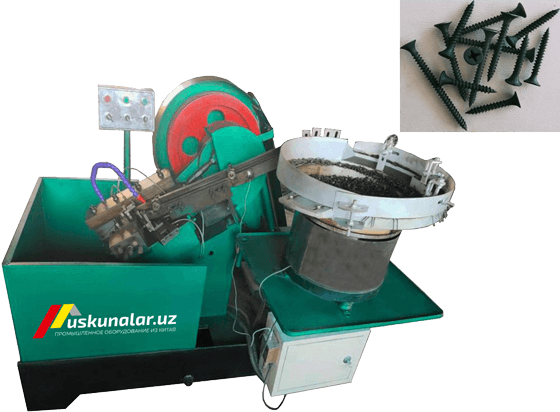

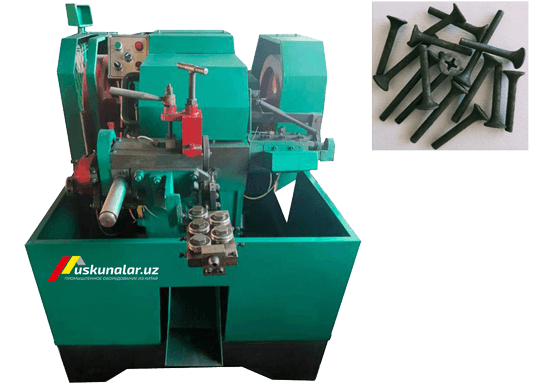

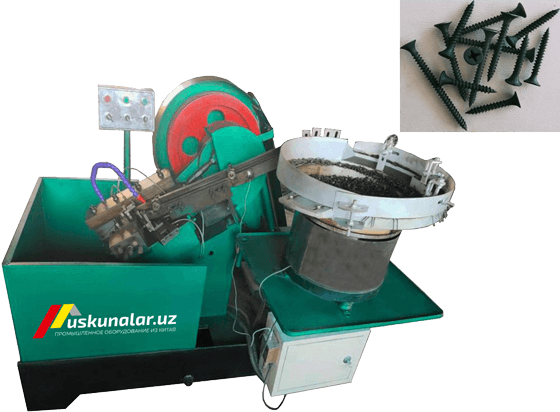

The next step of this self-drilling production line is the equipment for the production of drywall screws. This equipment is used to cut wires to the desired length and shape in the manufacture of drywall screws. The cold heading machine US-TOPS-CH50 is then used to form the head of the screw. This machine is designed to create a consistent head shape and size. The cold heading machine US-TOPS-CH76 is then used to form the threads on the screw.

After that, the thread rolling machine US-TOPS-TR52 is then used to roll the threads on the screw. The drying machine is then used to dry the screws before they are sent to the mesh-belt furnace. The mesh belt furnace is used to heat treat screws to increase their strength and durability.

The final step of this screw production line is the screw electro-galvanizing line. This process is used to coat the screws with a protective layer of zinc. This layer helps to protect the screws from corrosion and other environmental factors.

In general, the self-drilling, the drywall screw production line is a complex process that requires a variety of tools and processes to produce a high-quality product. The raw material, wire drawing machine, drywall screw making machine, cold heading machines, thread rolling machine, drying machine, mesh-belt furnace, and screw electro galvanized production line are all essential components of the production line.

|

MACHINE COMPONENTS

|

| 1. |

Raw material |

2.9 mm black wire |

| Wire drawing machine |

| 2. |

Drywall screw making machine |

Cold heading machine US-TOPS-CH50 |

| Cold heading machine US-TOPS-CH76 |

| Cold heading machine US-TOPS-CH100 |

| Thread rolling machine US-TOPS-TR52 |

| Thread rolling machine US-TOPS-TR102 |

| Drying machine |

| 3. |

Mesh-belt Furnace |

| 4. |

Screw electro galvanized production line |

|

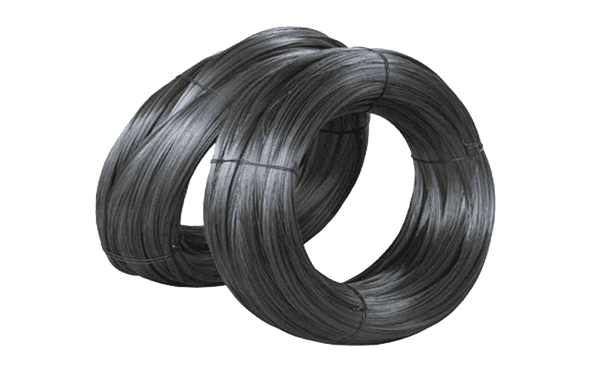

RAW MATERIAL

|

| 1. |

Steel wire SAE1022A |

2.9 mm |

10 ton |

|

Wire drawing machine - draw 2.9 mm to 2.7 mm

|

| 1. |

Drum outside diameter |

560 mm |

| 2. |

Units quantity |

1 draws |

| 3. |

Inlet wire diameter |

2.9 mm |

| 4. |

Outlet wire diameter |

2.7 mm |

| 5. |

Motor power |

7.5 KW x 1 |

| 6. |

Voltage |

380 V / 50 Hz |

| 7. |

Dimensions |

1 draws is 3600 x 1300 x 2000 mm |

| 8. |

Weight |

1000 kg |

| 9. |

Production capacity |

3.0 tons / 8 hours |

| 10. |

Lifting wire device |

1 pc |

|

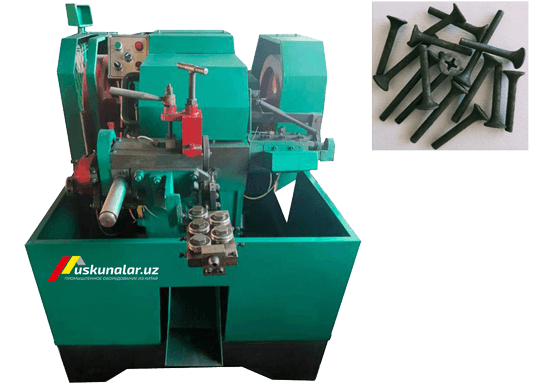

DRYWALL SCREW MAKING MACHINE

COLD HEADING MACHINE

|

| 1. |

Model |

US-TOPS-CH50 |

US-TOPS-CH76 |

US-TOPS-CH100 |

|

| 2. |

Wire diameter |

2.5 - 3.5 mm |

2.5 - 5.0 mm |

2.9 - 5.0 mm |

| 3. |

Nail length |

15 - 50 mm |

50 - 85 mm |

85 - 110 mm |

| 4. |

Working speed |

150 pcs / min |

130 pcs / min |

110 pcs / min |

| 5. |

Motor power |

2.2 KW |

2.2 KW |

2.2 KW |

| 6. |

Dimensions |

1700 x 1400 x 1450 mm |

2100 x 1100 x 1500 mm |

2100 x 1100 x 1500 mm |

| 7. |

Weight |

1700 kgs |

2000 kgs |

2000 kgs |

|

THREAD ROLLING MACHINE

|

| 1. |

Model |

US-TOPS-TR52 |

US-TOPS-TR102 |

|

| 2. |

Wire diameter |

2.7 - 4.2 mm |

3.2 - 6.0 mm |

| 3. |

Nail length |

17 - 52 mm |

52 - 102 mm |

| 4. |

Working speed |

180 - 200 pcs / min |

180 - 200 pcs / min |

| 5. |

Output |

30 kg / hour |

30 kg / hour |

| 6. |

Motor power |

3 KW |

3 KW |

| 7. |

Dimensions |

1900 x 1400 x 1450 mm |

1900 x 1400 x 1450 mm |

| 8. |

Weight |

900 kgs |

900 kgs |

|

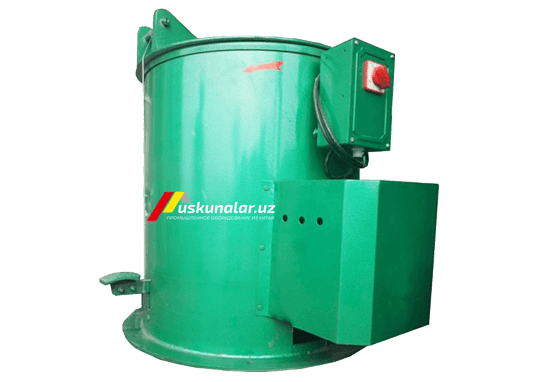

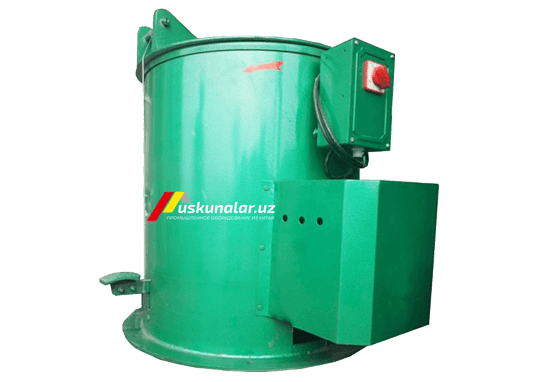

SPIN-DRY MACHINE

|

| 1. |

Model |

US-TOPS-D70 |

|

| 2. |

Capacity |

50 - 70 kg |

| 3. |

Inner drum size |

Φ500 mm x 400 mm |

| 4. |

Rotating speed |

530 r / min |

| 5. |

Motor power |

1.1 KW |

| 6. |

Electric wire power

|

3 KW |

| 7. |

Dimensions |

800 x 1000 x 850 mm |

| 8. |

Weight |

150 kg |

|

MESH-BELT FURNACE

|

| The mesh-belt furnace is special used for batch production small and medium metal parts, such as screw, standard fasteners, bearing, etc. |

Feeding part |

1set |

| Mesh-belt quenching furnace |

1set |

| Water (oil) tank lifting |

1set |

| Mesh-belt tempering furnace |

1set |

| PID electrical cabinet |

1set |

|

Feeding part + RCWF9 Mesh-belt quenching furnace

|

| Furnace shell is steel structure ,the base and structure adopt channel steel. There is rib stiffened laminate inside the furnace shell. There is flexible seal bolt to lock the up and down furnace body, it is very easy maintance. The furnace body and lining use high-alumina brick, and aluminium silicate needle-felted carpet to keep warm. The heating pipe is made of CR20Ni80 Nickel-chromium resistance wire. Heating method is up and down heating. Heating power is 75 KW, and three areas control the temperature separately. There is sic plate on the brick, and muffle on sic plate. The material of muffle is 310S stainless steel plate, thickness is 8 mm. Also have high alumina ball and 310S stainless steel ball box. There is 310S removable furnace bottom plate, pipe valve for protect gas and methyl alcohol cracking unit. The mesh belt width is 300 mm, and material is 314 Stainless steel with herringbone structure and mechanical stepping frequency control device. Power is 0.75 KW. |

Heating power |

75 KW |

| Voltage |

380 V / 50 Hz |

| Max operating temperature |

950 ℃ |

| Working temperature |

750 ~ 850 ℃ |

| Temperature controlling area |

3 areas |

| Temperature controlling tolerance |

± 2 ℃ |

| Furnace temperature homogeneity |

± 5 ℃ |

| Width of the mesh |

300 mm |

| Material of mesh |

Stainless steel 314, herringbone |

| Driver power |

0.75 KW |

| Muffle effective size |

350 x 120 mm |

| Methyl alcohol dosage |

approx 3 kg / hour |

| Output |

approx 120 - 150 kg / hour |

|

|

|

Water (oil) tank and lifting

|

| The tanks is steel structure and base is channel steel.The mesh belt width is 300mm,and material is 314 Stainless steel with herringbone structure. mechanical stepping frequency control device.The motor power is 0.75kw. |

|

Furnace shell is steel structure, the base and structure adopt channel steel. There is rib stiffened laminate inside the furnace shell, Alumina silicate fibre keep warm. These is heating chamber in the furnace, 2.2 KW heated air circulation fan and wind direction guide plate. The heating rod is made of CR20Ni80 Nickel-chromium resistance wire. Heating power is 40 KW. The mesh belt width is 450 mm, and material is galvanized A3 with herringbone structure and mechanical speed governors chain wheel transmission. The power is 0.75 KW.

|

Mesh-belt tempering furnace

|

| 1. |

Heating power |

40 KW |

|

| 2. |

Voltage |

380 V / 50 Hz |

| 3. |

Max operating temperature |

650 ℃ |

| 4. |

Working temperature |

400 ~ 500 ℃ |

| 5. |

Temperature controlling area |

1 area |

| 6. |

Temperature controlling tolerance |

± 2 ℃ |

| 7. |

Furnace temperature homogeneity |

± 5 ℃ |

| 8. |

Width of the mesh |

450 mm |

| 9. |

Material of mesh |

Galvanized A3, herringbone |

| 10. |

Circulating fan power |

2.2 KW |

PID electrical cabinet

Four area (three area for quenching, one area for tempering) control the temperature separately. Adopt the intelligent temperature controller, Solid-state relay, Pid adjust the power and control temperature automatically. Also have the device for adjusting power manually. Control the temperature for quenching and tempering automatically. Besides also control each area’s mesh belt frequency conversion and water (oil) pump. If the furnace is over temperature, it will alarm automatically.

|

SCREW ELECTRO GALVANIZED PRODUCTION LINE

|

| 1. |

Model |

US-TOPS-EGN-2/1 |

| 2. |

Type of galvanization |

rotating galvanization |

| 3. |

Size of nail |

all sizes |

| 4. |

Material of tank |

PE, thickness 15 mm |

| 5. |

Rotating drum |

size: Φ500 mm x 1100 m |

| capactity: 120 - 150 kg / drum |

| quantity: 3 drums (2 pcs on machine, 1 pc as spare) |

| 6. |

Production capacity |

300 kgs per time |

| 7. |

Production time |

2 hours per time |

| 8. |

High frequency rectifier |

1000 KVA x 1 pc |

| 9. |

Power supply |

380 V / 50 Hz, 3 phase |

| 10. |

Total motor power |

13.6 KW |