Uskunalar.uz's catalog is constantly being enriched with information on the world's most innovative equipments and technologies in 2026. Save time and money with us!

Catalog

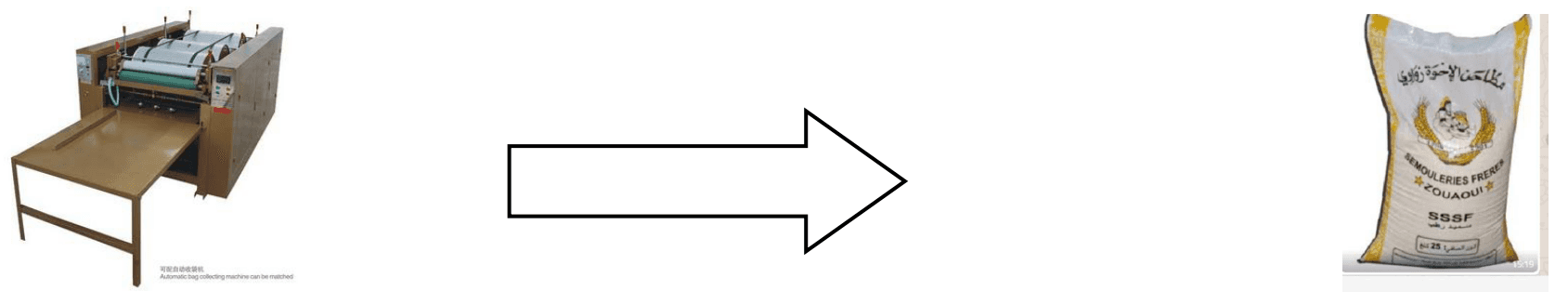

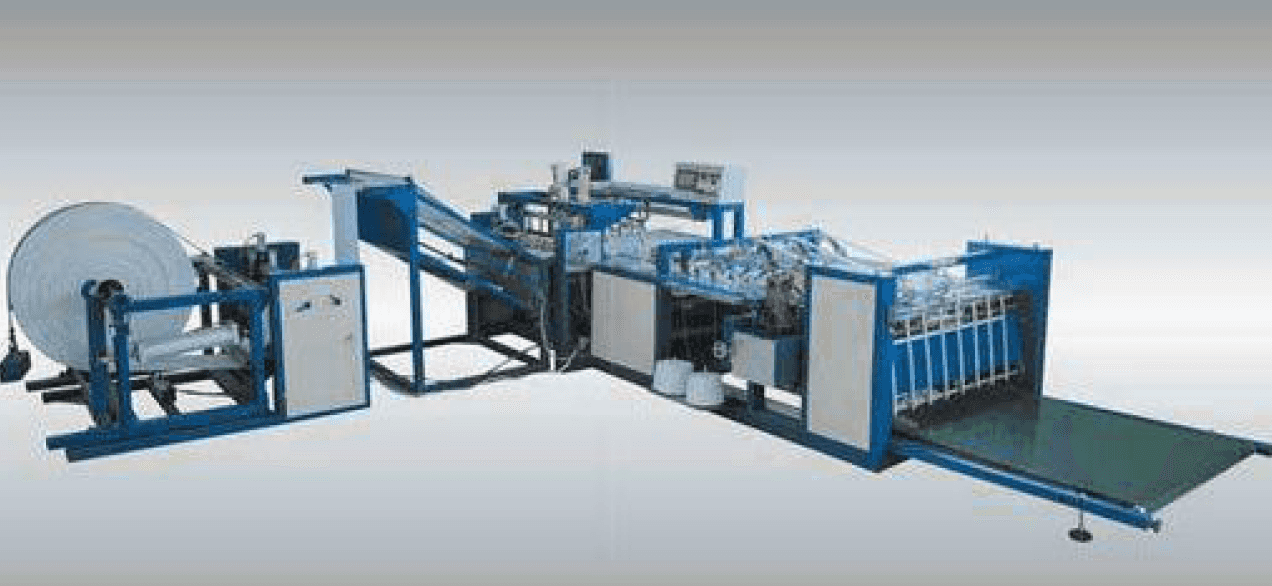

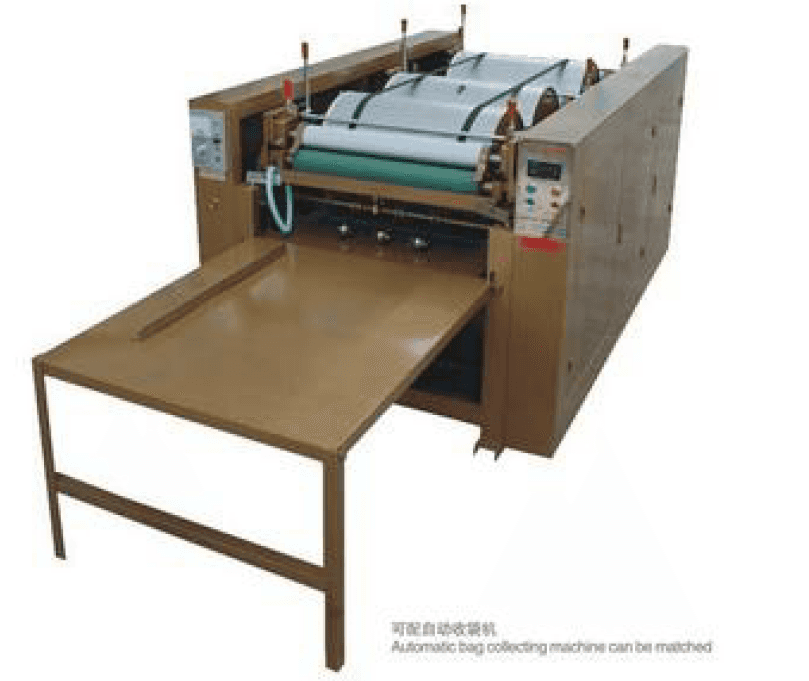

- Packaging industry

- Metal processing

- Food industry

- Refrigerators

- Bread production

- MEMAK

- Construction equipment

- Wood processing and furniture manufacturing industry equipment

- Special technique

- Paper industry

- Production of confectionery products

- Mills for grinding wheat

- Production of sausages and meat products

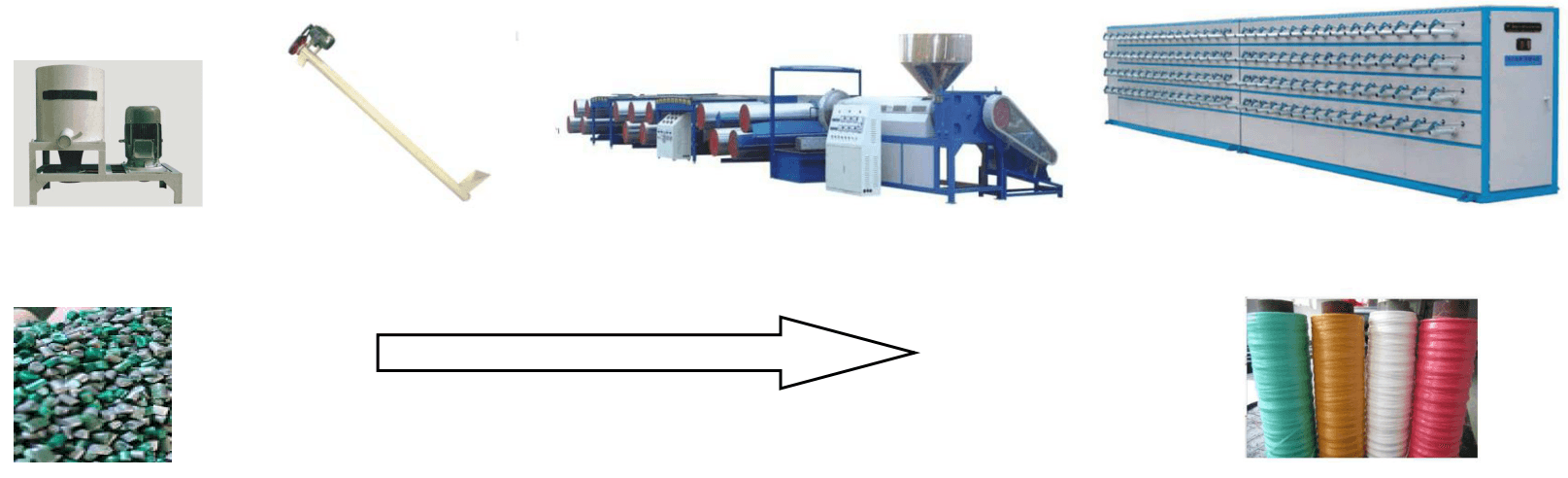

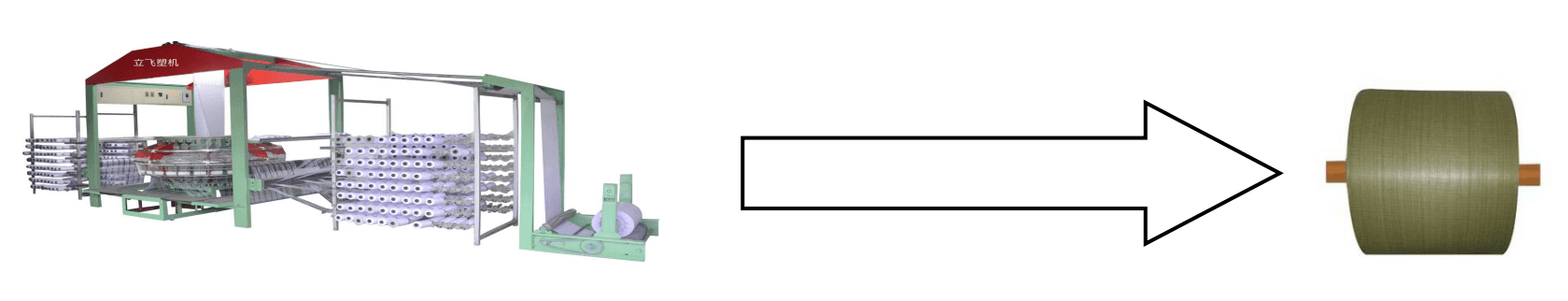

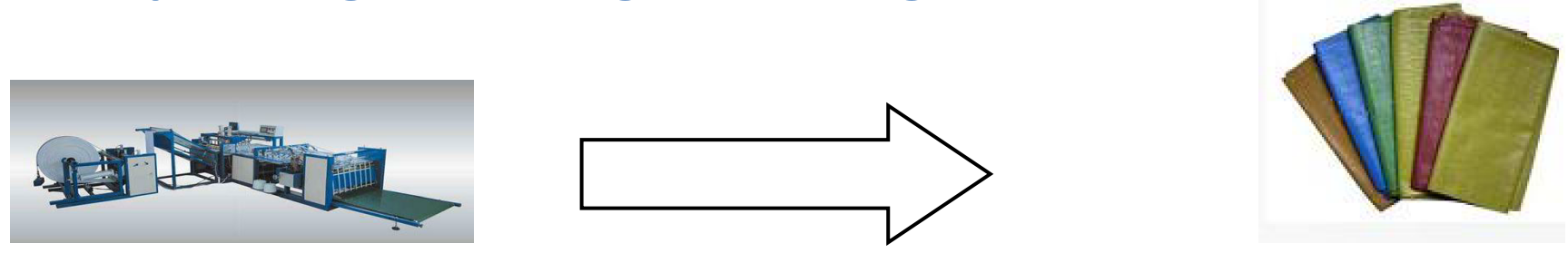

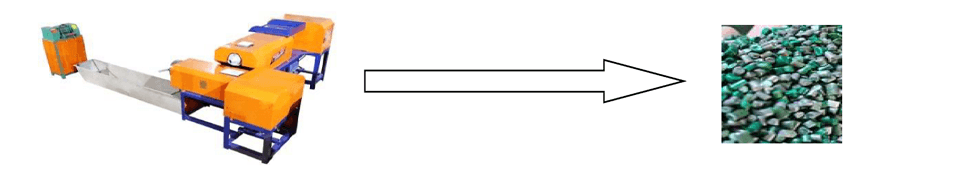

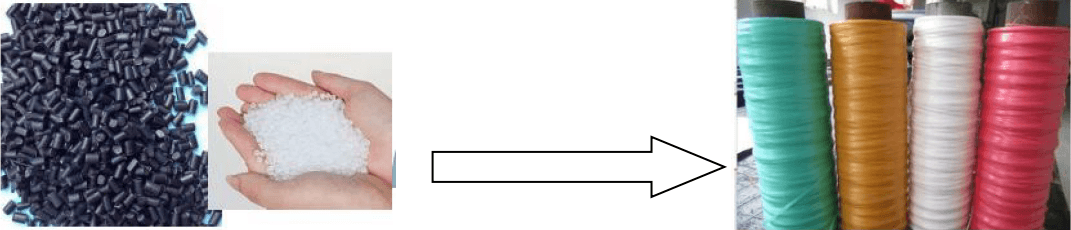

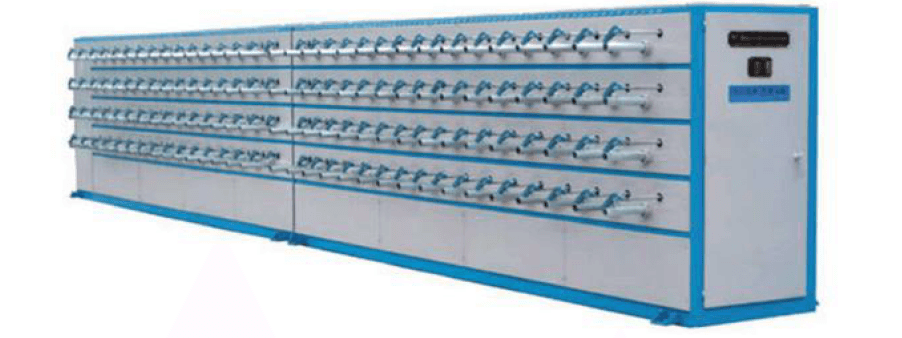

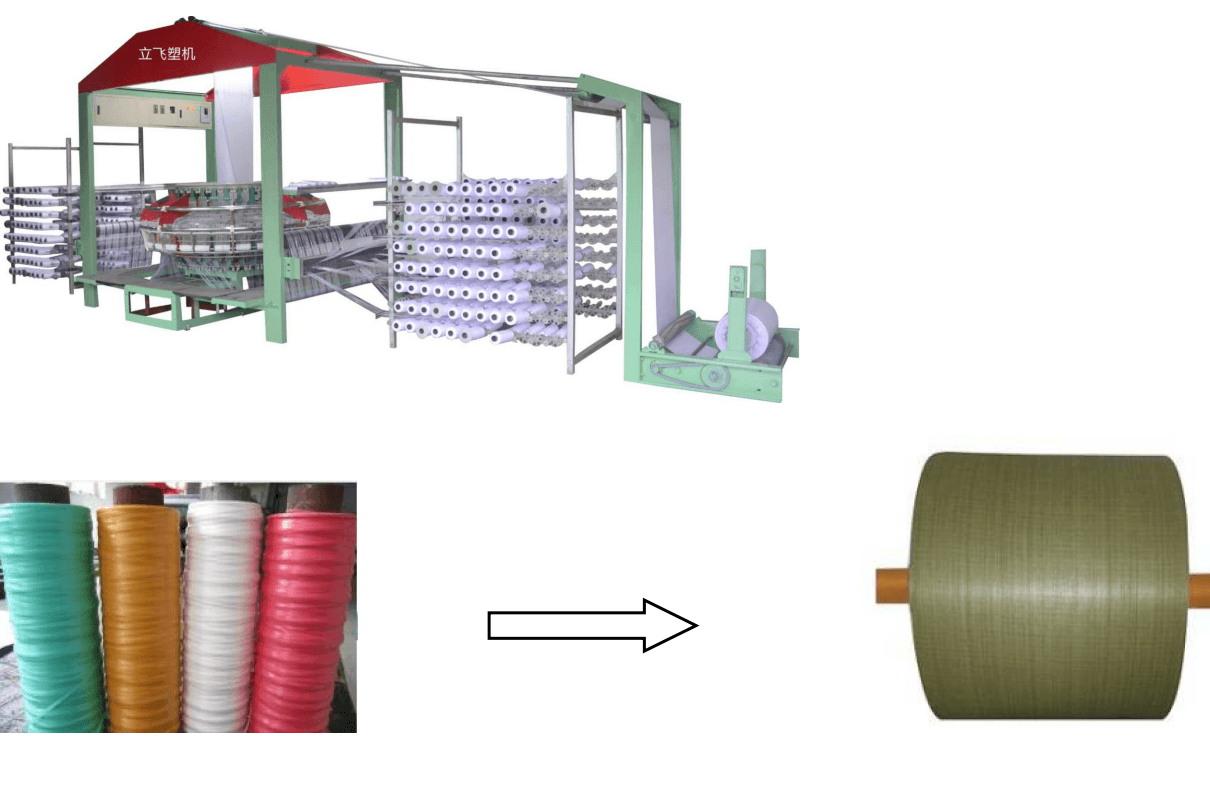

- Production of polyethylene products

- Laser equipment

- Production of plastic products

- Agricultural equipment

- Equipment for the and clothing industry

- Production of disposable tableware

- Filtration equipment

Contact us

Tashkent city, Sirgali district, Katta Almas 1-tor street 9a.

Copyright © 2005 - 2026 Uskunalar.uz Group LLC. All rights reserved