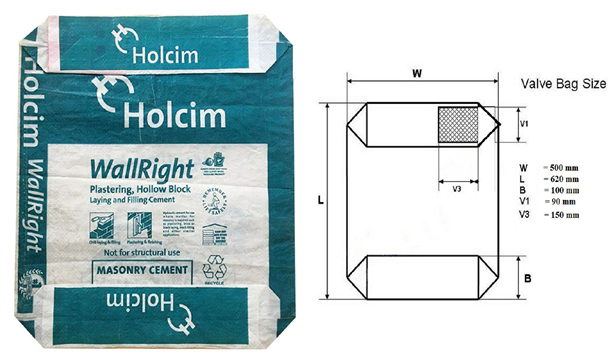

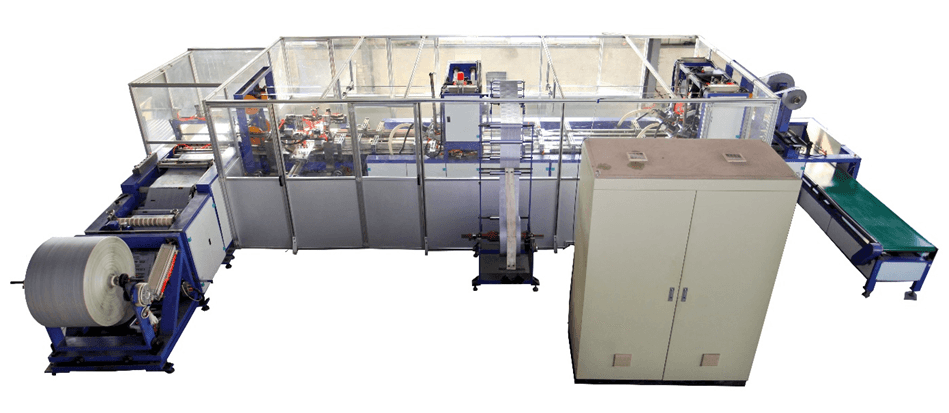

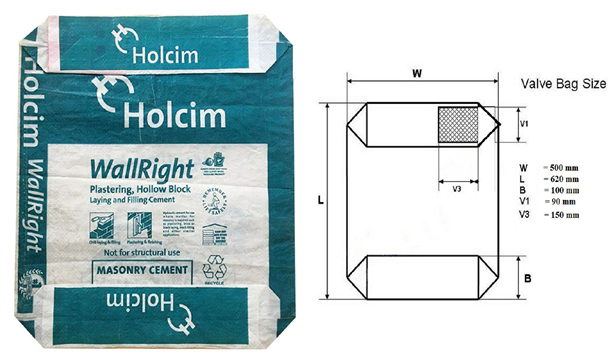

These bags are different from ordinary, that is, local bags. Building materials are mainly packed in such bags: cement, lime, plaster, various dry mass glues, gypsum and many other products. This line is responsible for the production of such bags and has the capacity to produce up to 80,000 bags per day, that is, in 24 hours. The line consists of many pieces of equipment, and the following description shows each piece of equipment in separate parameters.

| Basic parameters |

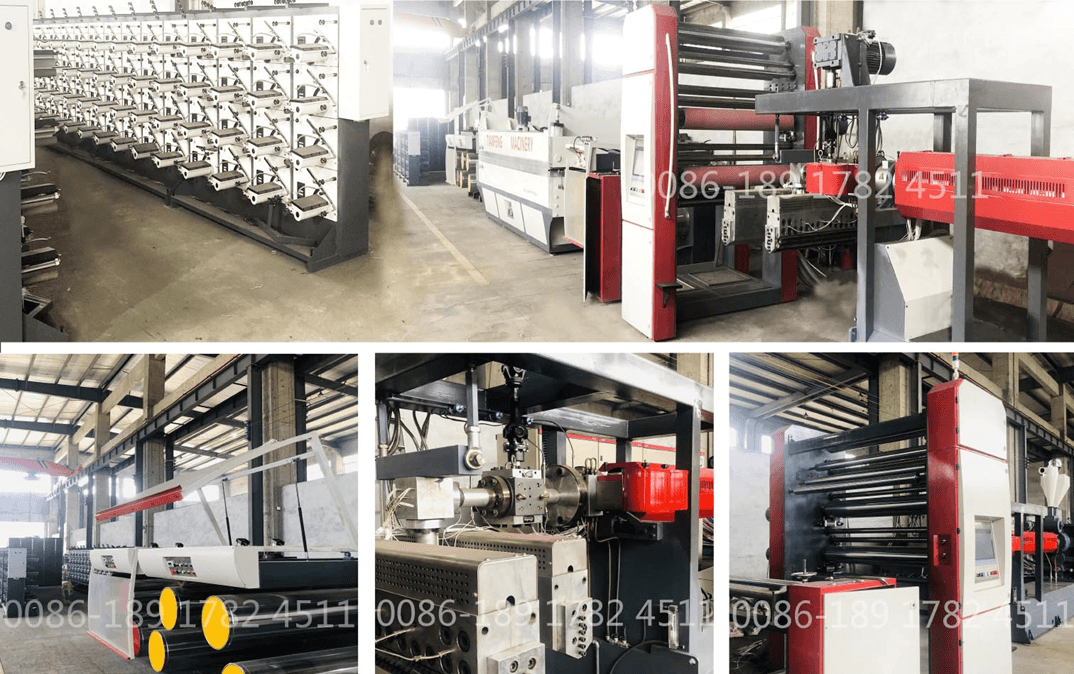

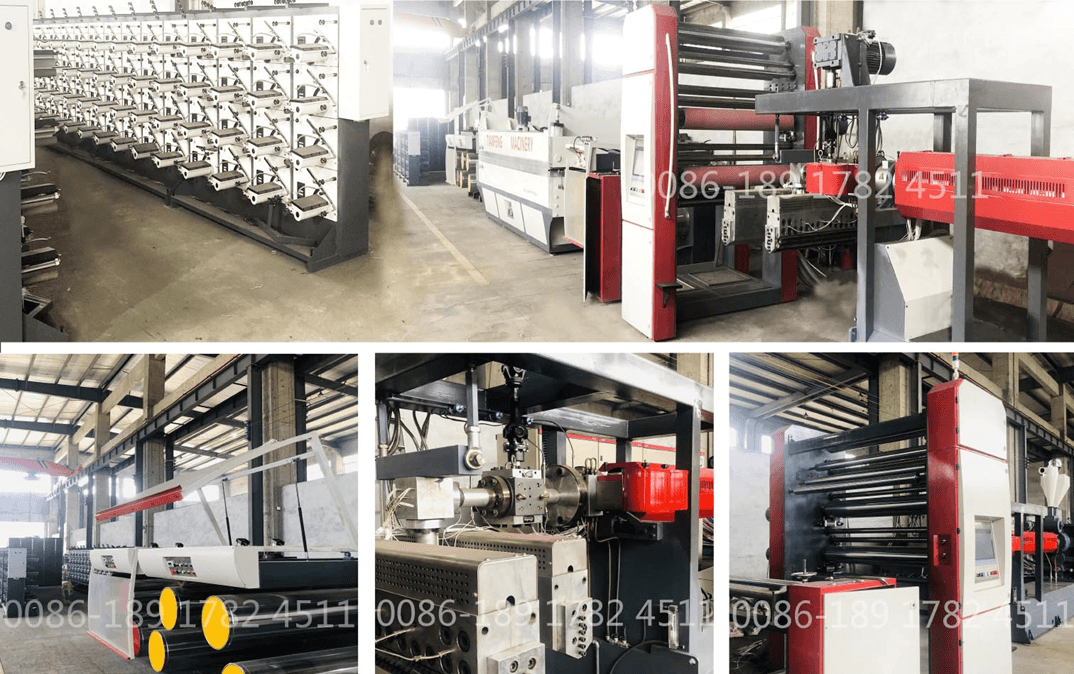

| 1. High speed flat yarn extruder with winder machine |

|

Output |

450 kg/hour |

| Raw material........................................ |

PP................................................... |

| Tape width |

2.5-4 mm |

| Working capacity |

230 kW |

| Voltage |

380V |

| Air pressure |

0.6-0.8 Mpa |

| Total air supply |

0.5 m3/min |

| Total water supply |

0.6 m3/min |

| Water pressure |

3-5 bar |

| Inlet water temperature |

18-22°C |

| Machine dimension |

39000*3900*2600mm |

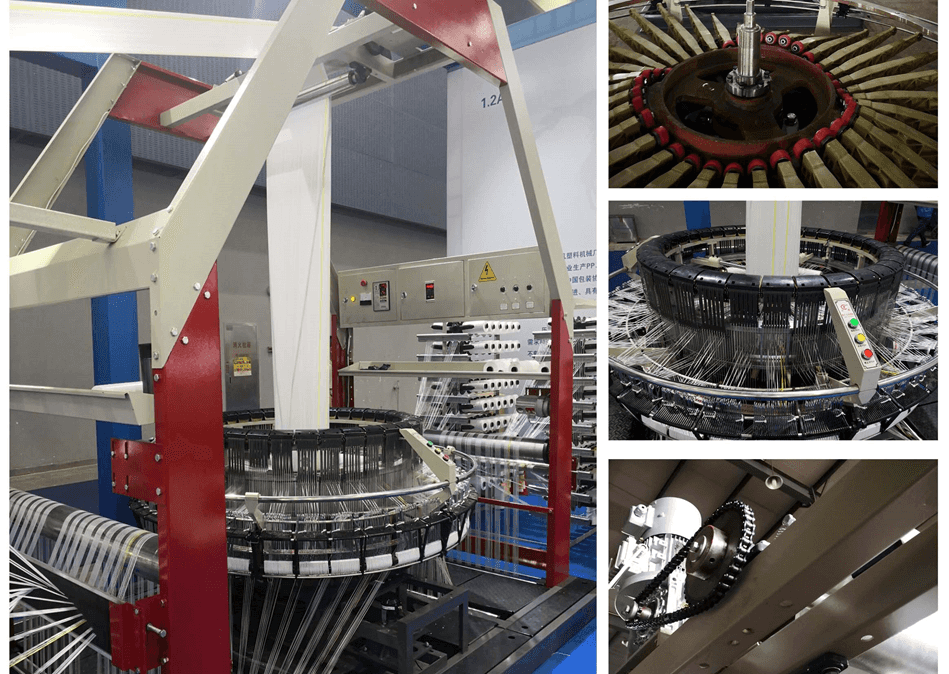

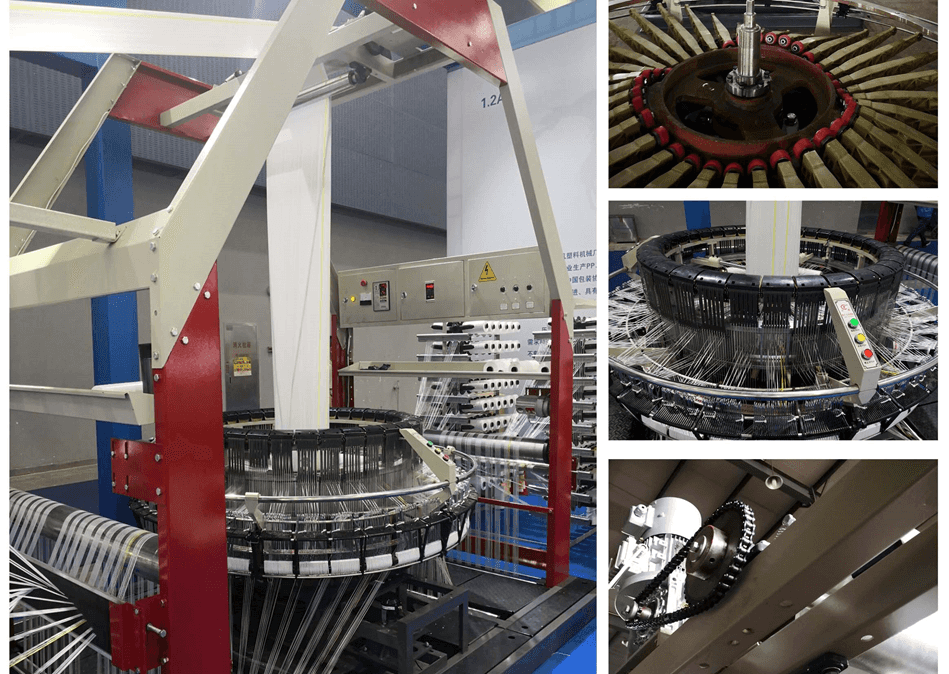

| 2. Six shuttle circular loom |

|

Model |

US-S-YZJ-850/6S |

| Number of shuttles |

6 pcs |

| Rotational speed |

120-180 rpm |

| Max. number of warp |

720 pcs |

| Working width |

350-850 mm |

| Driving main motor |

3 kW |

| Length of winding core |

950 mm |

| Over dimension |

9100*2410*3100 mm |

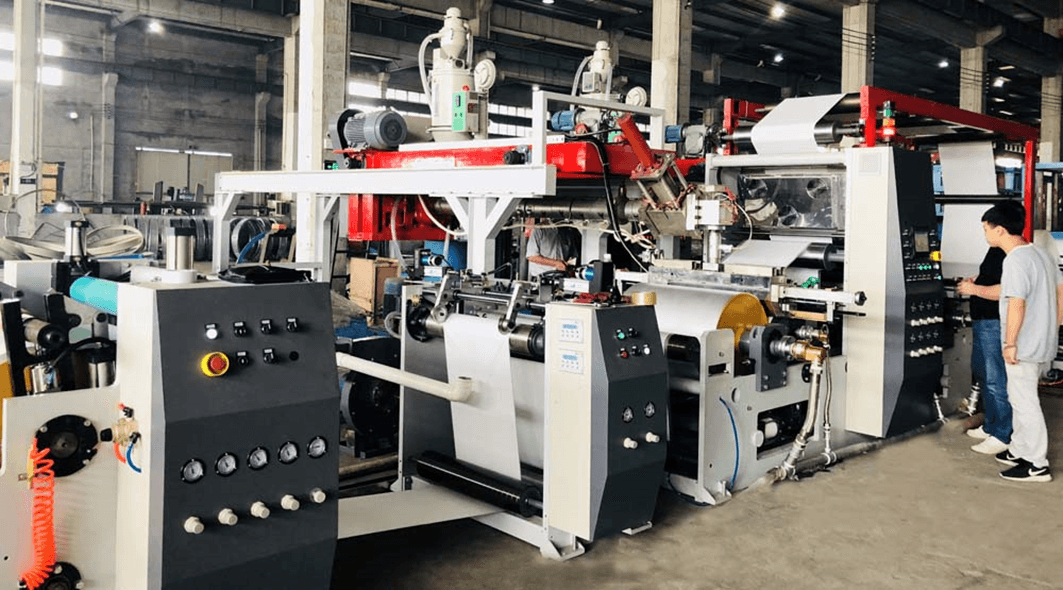

| 3. Laminating machine (two extruder with two die) |

|

Max. extrusion capacity |

70 kg/hour |

| Max. coating width |

800 mm |

| Coating thickness |

0.012-0.03 mm |

| Coating linear speed |

20-150 m/min |

| Length of roller |

900 mm |

| Max. width of material |

800 mm |

| Voltage |

380V |

| Installed power |

120 kW |

| Power consumption |

60 kW |

| Cooling water supply |

0.5 m3/min |

| Overall dimension |

12500*7500*2800 mm |

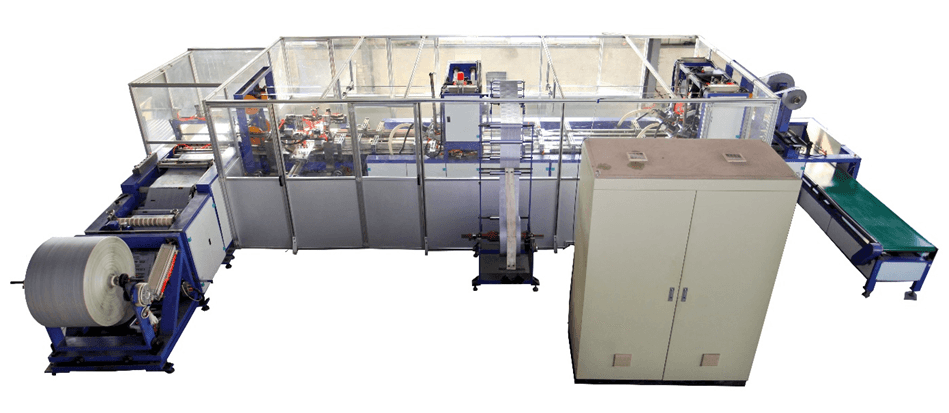

| 4. PP block bottom valve bag making machine |

|

Max. working speed |

50-80 pcs/min |

| Bag width |

350-600 mm |

| Bag length |

450-910 mm |

| Bottom width |

80-180 mm |

| Voltage |

380V |

| Installed power |

85 kW |

| Cooling water supply |

maks. 18°C; 4 bars |

| Overall dimension |

13000*8500*2500 mm |

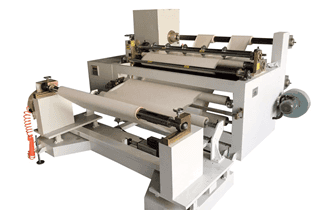

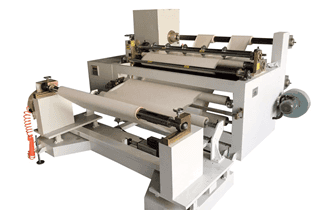

| 5. Slitting machine |

|

Max. width of roll material |

700 mm |

| Slitting width |

40-600 mm |

| Max. slitting speed |

100 m/min |

| Voltage |

380V |

| Power |

3.5 kW |

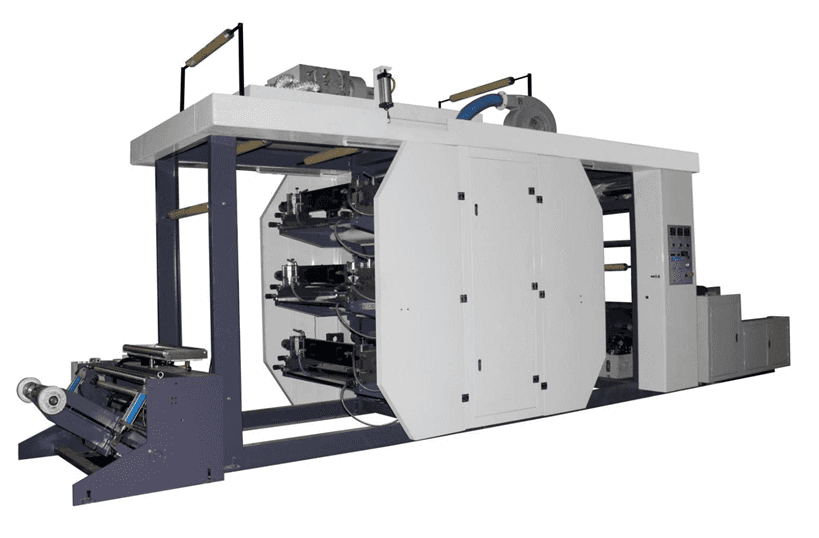

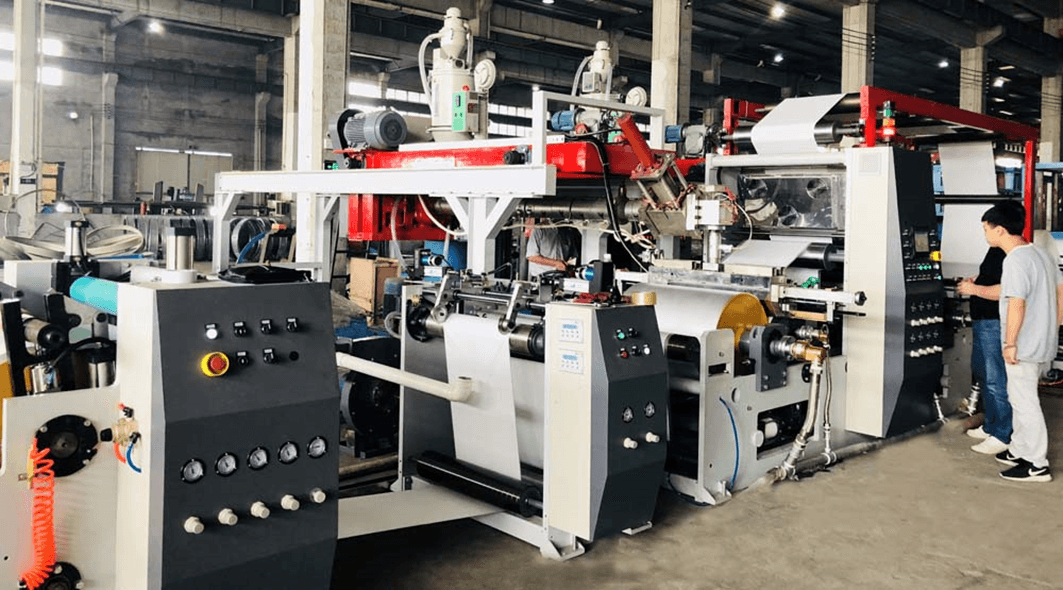

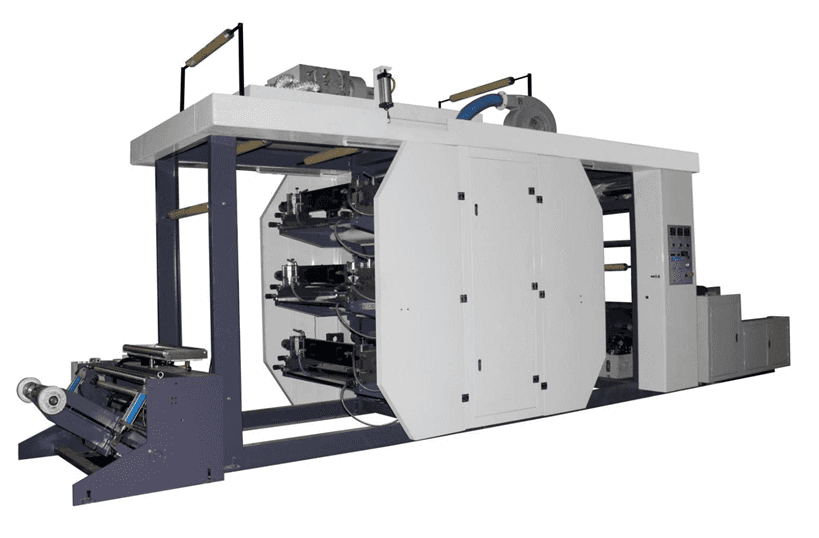

| 6. Six colors roller to roller printing machine |

|

Max. width of printing material |

800 mm |

| Max. width of printing |

760 mm |

| Max. length of repeat printing |

500-1300 mm |

| Speed of printing |

30-120 m/min |

| Voltage |

380V |

| Power |

25 kW |

| Power consumption |

20 kW |

| Overall dimension |

6800*2150*2600 mm |

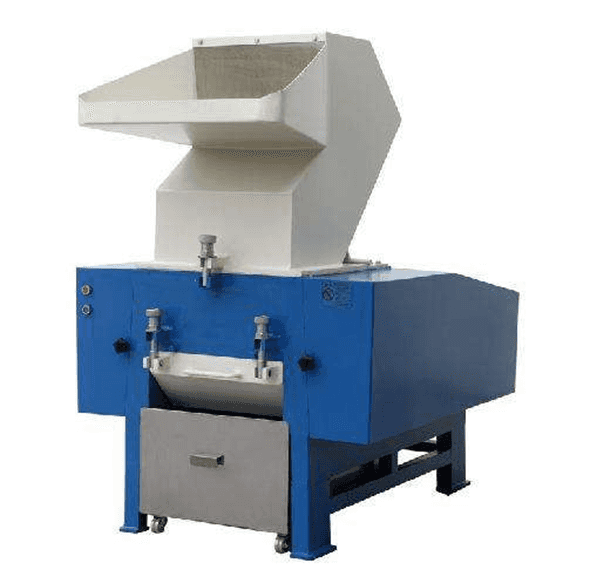

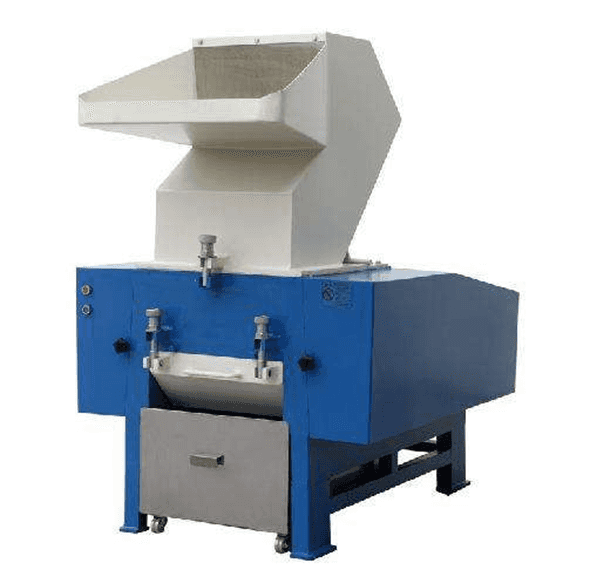

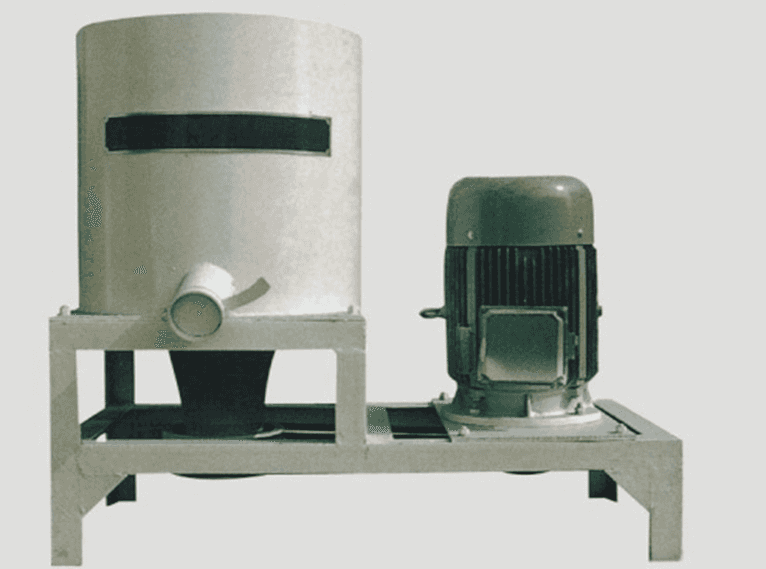

| 7. Plastic crusher machine |

|

Size of feed inlet |

300*600 mm |

| Production capacity |

150-300 kg/hour |

| Voltage |

380V |

| Installed power |

15 kW |

| Dimension |

1300*1200*1600 mm |

| Machine weight |

800 kg |

| 8. Drying mixer machine |

|

Heating type |

by friction |

| Capacity |

150-300 kg/hour |

| Voltage |

380V |

| Dimension |

1500*600*1400 mm |

| Weight |

300 kg |

| 9. Hydraulic bag baling machine |

|

Dia. of oil cylinder |

125 mm |

| Max. working pressure |

6-8 Mpa |

| Height of working |

900 mm |

| Working platform size |

1200*800 mm |

| Installed power |

2.2 kW |

| Overall dimension |

2200*930*2300 mm |

| 10. Model recycling machine |

|

Model |

US-SJ-FB-100B |

| Dieameter of screw |

100 mm |

| Rotational speed |

50-70 rpm |

| Power of main motor |

18.5 kW |

| Power of sub-motor |

7.5 kW |

| Power of grain cutting |

0.5 kW |

| Heating power |

24 kW |

| Production capacity |

50-100 kg/hour |

| Weight |

1000 kg |

| Overall dimension |

5500*2000*1100 mm |

| Finished product |

|

|

|